1、 Basic information of the standard:

Standard name: Environmental testing methods for marine instruments Part 10: Salt spray test

Standard number: GB/T 32065.10-2020

Centralized unit: National Marine Standardization Technical Committee

Executive unit: National Marine Standardization Technical Committee

Department in charge: Ministry of Natural Resources (Marine)

This standard was issued on November 19, 2020 and implemented on June 1, 2021.

Scope of this standard:

This standard specifies the test requirements, process, and related information for salt spray testing of marine instruments and components.

This standard is applicable to evaluating the ability of marine instruments and components to resist salt spray corrosion and the impact of salt spray on the performance and function of marine instruments and components.

Test method:

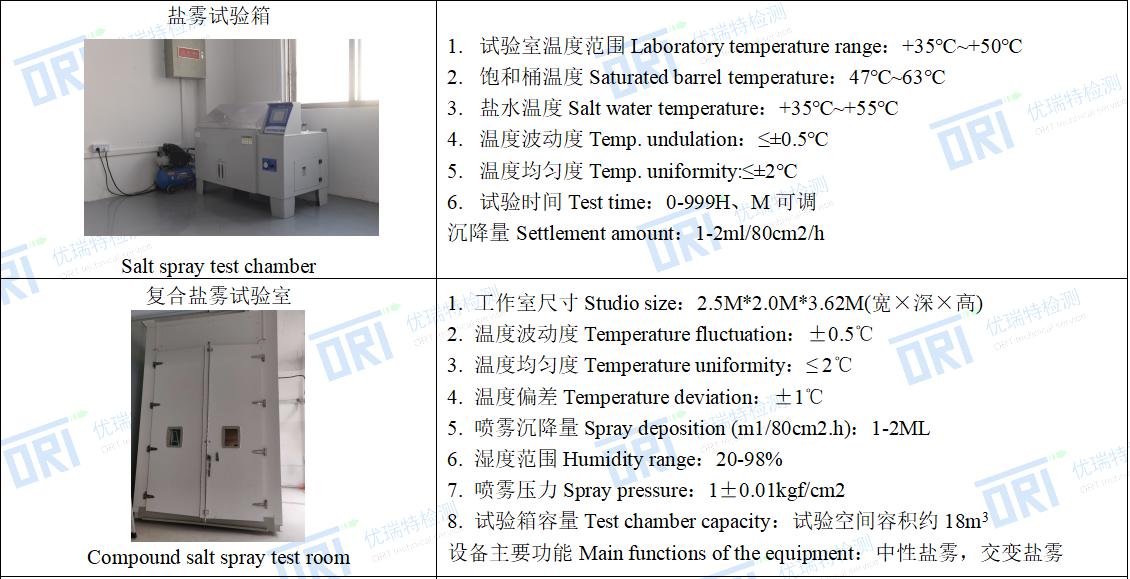

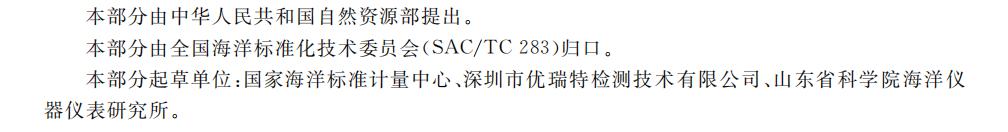

1. The test equipment is a combination of salt spray test chamber and damp heat test chamber

2、 Failure mode of salt spray test:

Marine instruments are mostly located in highly corrosive marine salt spray environments during their lifespan. Salt mist can reduce the performance of both metallic and non-metallic materials. The mechanism of salt spray corrosion of metal materials is electrochemical corrosion, while the degradation of non-metallic materials is caused by the complex chemical reaction between salt and materials. The impact of salt spray corrosion on instruments mainly includes corrosion caused by electrochemical reactions and accelerated stress corrosion. This failure mode can lead to a decrease in the product's ability to withstand the environment, resulting in a decrease in product performance and affecting the normal function and structural integrity of the product; Salt deposits cause damage to the electrical components of the instrument, as well as blockage or jamming of the transmission parts of mechanical components and components; The corrosion of insulation materials and contact metal can lead to changes in the electrical properties of the product and even fail to meet usage requirements, such as a decrease in insulation resistance and an increase in contact resistance; In addition, salt spray corrosion can also cause surface coatings to blister, peel, and peel off, leading to fading, blurring, illegibility, and detachment of product markings and imprints, thereby affecting the appearance of the product.

3、 Precautions for salt spray testing of marine instruments:

Most marine instruments are used outdoors, and salt spray, mold growth, and sand dust environments can coexist. Due to the mutual influence between the salt spray test, mold growth test, and sand dust test, for example, the surface of the instrument after the sand dust test may cause scratches on the surface coating or metal surface of the test piece due to the friction of the sand dust, which can cause misjudgment of the results of the salt spray test. After the mold growth test, the surface of the instrument may undergo mold corrosion due to mold growth, which can also affect the results of the salt spray test. If the sample after the salt spray test is not thoroughly cleaned, the residual salt will affect the growth of mold and affect the results of the mold test. Therefore, when conducting these three tests with the same sample, the mutual influence between the tests should be minimized as much as possible. The test samples should be thoroughly cleaned between the three tests, and the test results generated from each test should be compared and analyzed to distinguish the sample's impact on different tests.

4、 ORT salt spray test capability:

5、 Standard drafting unit:

6、ORT participated in drafting and published standards:

1. GB/T 35774-2017 'Specification for Performance Testing of Transport Packaging Components'

2. GB/T 4857.1-2019 'Basic Testing of Packaging, Transportation, and Packaging Components - Part 1: Marking Methods for Various Parts during Testing'

3. GB/T 4798.1-2019 'Classification of Environmental Conditions - Classification of Environmental Parameter Groups and Classification of Their Severity - Part 1: Storage'

4. GB/T 2421-2020 'Overview and Guidelines for Environmental Testing'

5. GB/T 2423.27-2020 'Environmental Testing - Part 2: Test Methods, Test Methods and Guidelines: Temperature/Low Pressure or Temperature/Humidity/Low Pressure Combined Tests'

6. GB/T 2423.51-2020 'Environmental Testing - Part 2: Test Methods - Test Ke: Flow Mixed Gas Corrosion Test'

7. GB/T 32065.8-2020 Marine Instruments - Environmental Testing Methods - Part 8: Temperature Change Test

8. GB/T 32065.10-2020 Marine Instruments - Environmental Testing Methods - Part 10: Salt Spray Test

9. GB/T 4797.9-2021 Classification of Environmental Conditions - Natural Environmental Conditions - Shock and Vibration Data Measured during Storage, Transportation, and Use

10. GB/T 2423.33-2021 Environmental Testing Part 2: Test Methods Test Kca: High Concentration Sulfur Dioxide Test

11. GB/T 2423.18-2021 Environmental Testing Part 2: Test Methods Test Kb: Salt Spray, Alternating (Sodium Chloride Solution)

12. NB/T 10279-2019 'Wet and Hot Environmental Conditions for Transmission and Transformation Equipment'

13. NB/T 10280-2019 'Wet and Hot Environmental Conditions and Technical Requirements for State Monitoring Devices Used in Power Grids'

14. YZ/T 0174-2020 Technical Requirements for Cold Chain Delivery Insulation Box

15. T/CPF 0012-2020 Guidelines for Testing Small Transport Packages for Express Delivery

16. T/CPF 0011-2020 Guidelines for Testing Electrical Transportation Packaging in E-commerce Logistics