1、 Basic information of the standard:

Standard name: Packaging, transportation, basic testing of packaging components Part 1: Marking methods for various parts during testing

Standard number: GB/T 4857.1-2019

This standard replaces the labeling methods for various parts of packaging and transportation packages during testing (GB/T 4857.1-1992).

This standard was issued on May 10, 2019 and implemented on December 1, 2019.

This standard is proposed and under the jurisdiction of the National Packaging Standardization Technical Committee (SAC/TC 49), and the competent department is the National Standardization Management Committee.

Scope of this standard:

This standard specifies the marking methods for various parts of transportation packaging during testing. Applicable to the labeling of various parts of the packaging, and the labeling of various parts of the packaging container can be used as a reference.

Labeling method:

1. Parallel hexahedral packaging

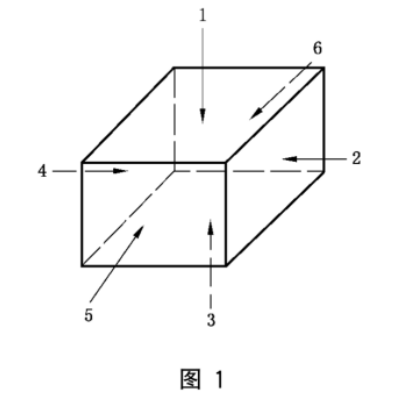

The packaging should be placed according to the state during transportation. If the transportation state is unclear, the packaging should be placed in the most stable state. After placement, if there are seams on the packaging that are perpendicular to the horizontal plane, any seam should be placed on the right side of the marked person; When the joint is parallel to the horizontal plane or without a joint, any smaller end face should be facing the marking personnel. The marking method is shown in Figure 1

The upper surface is marked as one surface; The right side is marked as 2 sides; The bottom surface is marked as 3 sides; The left side is marked as 4 sides; The near end face is marked as 5 faces; The distal face is marked as 6 faces.

The edges are represented by the numbers of the two faces that make up the edges, for example, 1-2 edges refer to the edges formed by the intersection of the first and second faces of the packaging.

The angle is indicated by the number of the three faces that make up the angle, such as the angle 1-2-5, which refers to the angle formed by the intersection of the first, second, and fifth faces of the packaging.

2. Cylindrical packaging

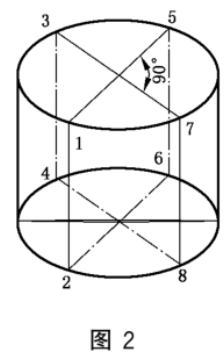

The packaging should be placed in an upright position, and the labeling method is shown in Figure 2.

The four endpoints of the two mutually perpendicular diameters on the top surface of a cylinder are represented by 1, 3, 5, and 7, while the four endpoints corresponding to the bottom surface of the cylinder are represented by 2, 4, 6, and 8. These endpoints are connected into four straight lines parallel to the axis of the cylinder, each represented by 1-2, 3-4, 5-6, 7-8.

If there are seams on the cylinder, one of them should be placed at the 5-6 line position, and the rest should be marked in the order described above.

3. Bag packaging

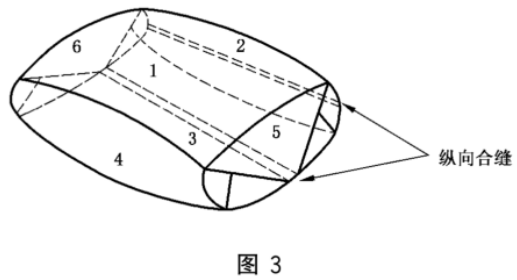

The packaging should be placed horizontally with the person facing the bottom of the bag.

If there are longitudinal seams on the bag packaging, when it is in the middle, it should be placed facing downwards; When it is on the edge, it should be placed to the right of the annotator. The marking method is shown in Figure 3

4. Envelope packaging

The packaging should be placed horizontally, with the personnel facing the open end of the envelope.

Place the seal upwards. The marking method is shown in Figure 4.

The upper surface is marked as one surface; The right edge is marked as 2 edges; The lower surface is marked as 3 faces; The left edge is marked as 4 edges; The opening end of the envelope is marked with 5 edges; The opposite edge of 5 edges is marked as 6 edges.

5. Packaging items in other shapes

Other shapes of packaging can be marked according to the characteristics and shape of the packaging, and can also be determined through consultation between the supply and demand parties.

2、 Standard drafting unit:

3、 GB/T 4857 series

The GB/T 4857 series is widely used in the testing of transportation packaging in China and is a routine inspection standard for transportation packaging in China. The purpose is to simulate and reproduce the hazards that may be encountered during the circulation process.

It mainly includes the following standards:

GB/T 4857.1 Packaging, Transportation, Packaging - Basic Tests - Part 1: Marking Methods for Each Part during Testing

GB/T 4857.2 Packaging - Basic Tests for Transport Packaging - Part 2: Temperature and Humidity Conditioning Treatment

GB/T 4857.3 Packaging - Basic Tests for Transport Packaging - Part 3: Static Load Stacking Test Method

GB/T 4857.4 Packaging - Basic Tests for Transport Packaging - Part 4: Compression and Stacking Test Methods Using a Pressure Testing Machine

GB/T 4857.5 Packaging Transport Packaging - Drop Test Method for Packaging Components

GB/T 4857.6 Packaging - Rolling Test Methods for Transport Packaging

GB/T 4857.7 Packaging, Transportation, Packaging - Basic Tests - Part 7: Sinusoidal Constant Frequency Vibration Test Method

GB/T 4857.9 Packaging - Basic Tests for Transport Packaging - Part 9: Spray Test Method

GB/T 4857.10 Packaging - Basic Tests for Transport Packaging - Part 10: Sinusoidal Variable Frequency Vibration Test Method

GB/T 4857.11 Packaging - Basic Tests for Transport Packaging - Part 11: Horizontal Impact Test Method

GB/T 4857.12 Packaging Transport Packaging - Immersion Test Method for Packaging Components

GB/T 4857.13 Packaging - Basic Tests for Transport Packaging - Part 13: Low Pressure Test Method

GB/T 4857.14 Packaging - Transport packages - Overturning test method

GB/T 4857.17 Packaging - Basic Tests for Transport Packaging - Part 17: General Rules for Developing Performance Test Programs

GB/T 4857.19 Packaging, Transportation, Packaging, and Distribution Test Information Record of Packaging Components

GB/T 4857.20 Packaging and Transportation Packaging - Collision Test Methods for Packaging Components

GB/T 4857.22 Packaging Transportation Packaging Unit Cargo Stability Test Method

GB/T 4857.23 Packaging - Basic Tests for Transport Packaging - Part 23: Random Vibration Test Method

4、 ORT Transportation Packaging Testing Capability:

1. Environmental processing capacity parameters

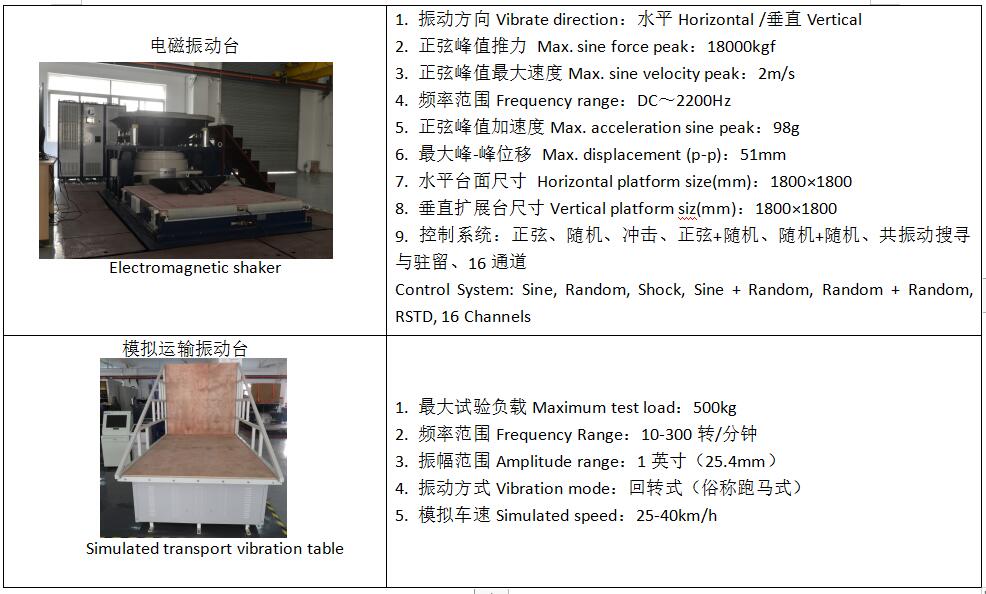

2、Vibration test capability parameters

3、Drop Test Capability Parameters

4、Clamping test capability parameters

5、Horizontal impact/inclined impact test capability parameters

6、Packaging compression test capability parameters

7、Forklift Handling Test Capability Parameters

5、 ORT participated in drafting and published standards:

1. GB/T 35774-2017 'Specification for Performance Testing of Transport Packaging Components'

2. GB/T 4857.1-2019 'Basic Testing of Packaging, Transportation, and Packaging Components - Part 1: Marking Methods for Various Parts during Testing'

3. GB/T 4798.1-2019 'Classification of Environmental Conditions - Classification of Environmental Parameter Groups and Classification of Their Severity - Part 1: Storage'

4. GB/T 2421-2020 'Overview and Guidelines for Environmental Testing'

5. GB/T 2423.27-2020 'Environmental Testing - Part 2: Test Methods, Test Methods and Guidelines: Temperature/Low Pressure or Temperature/Humidity/Low Pressure Combined Tests'

6. GB/T 2423.51-2020 'Environmental Testing - Part 2: Test Methods - Test Ke: Flow Mixed Gas Corrosion Test'

7. GB/T 32065.8-2020 Marine Instruments - Environmental Testing Methods - Part 8: Temperature Change Test

8. GB/T 32065.10-2020 Marine Instruments - Environmental Testing Methods - Part 10: Salt Spray Test

9. GB/T 4797.9-2021 Classification of Environmental Conditions - Natural Environmental Conditions - Shock and Vibration Data Measured during Storage, Transportation, and Use

10. GB/T 2423.33-2021 Environmental Testing Part 2: Test Methods Test Kca: High Concentration Sulfur Dioxide Test

11. GB/T 2423.18-2021 Environmental Testing Part 2: Test Methods Test Kb: Salt Spray, Alternating (Sodium Chloride Solution)

12. NB/T 10279-2019 'Wet and Hot Environmental Conditions for Transmission and Transformation Equipment'

13. NB/T 10280-2019 'Wet and Hot Environmental Conditions and Technical Requirements for State Monitoring Devices Used in Power Grids'

14. YZ/T 0174-2020 Technical Requirements for Cold Chain Delivery Insulation Box

15. T/CPF 0012-2020 Guidelines for Testing Small Transport Packages for Express Delivery

16. T/CPF 0011-2020 Guidelines for Testing Electrical Transportation Packaging in E-commerce Logistics