1、 Basic information of the standard:

Standard Name: Performance Testing Specification for Transport Packaging

Standard number: GB/T 35774-2017

This standard was issued on December 29, 2017 and implemented on April 1, 2018.

This standard is proposed and under the jurisdiction of the Standardization Technical Committee for Inspection Methods of Key Products in National Quality Supervision (SAC/TC 374), with the competent department being the National Standardization Management Committee.

Scope of this standard: This standard specifies the labeling of transportation packaging and the testing equipment, requirements, and reports for performance testing. This standard is applicable to rectangular transportation packages weighing less than 70kg without pallets. This standard does not apply to dangerous goods transportation packaging or other transportation packaging with special transportation requirements.

Test method:

The test items and sequence are shown in Table 1. At least one transportation packaging is required as a sample. Generally speaking, all standard test items are completed sequentially by the same transportation packaging (temperature and humidity tests are optional). After all test items are completed, inspections are conducted, and intermediate inspections are also allowed. Relevant parties can negotiate to determine the acceptance specifications for transportation packaging.

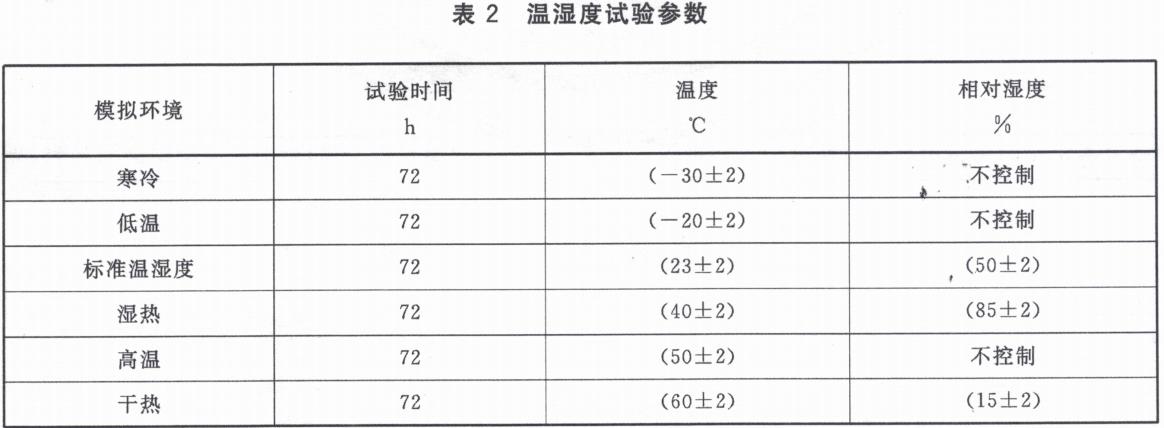

Test 1: Temperature and humidity test

Conduct a temperature and humidity test on the transportation packaging according to one or more temperature and humidity parameters in Table 2 as a pre-treatment. The total time for the combined test of multiple temperature and humidity parameters should not be less than 72 hours, and the test time for each temperature and humidity parameter should ensure that the transportation packaging can achieve thermal balance and maintain it for more than 12 hours during this test time. After the temperature and humidity test is completed, the next test should be carried out immediately and all other tests should be completed as soon as possible. For transportation packaging that is less affected by changes in environmental temperature and humidity, this test may not be conducted.

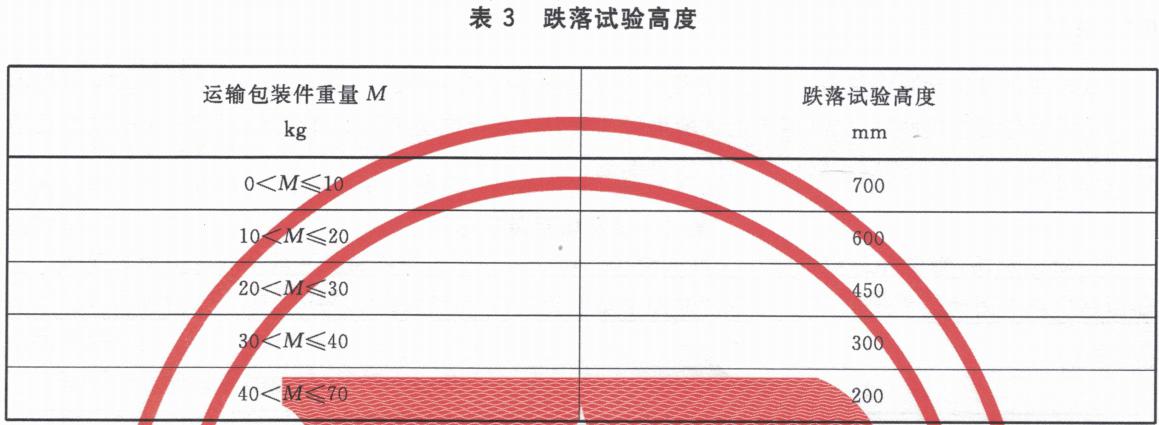

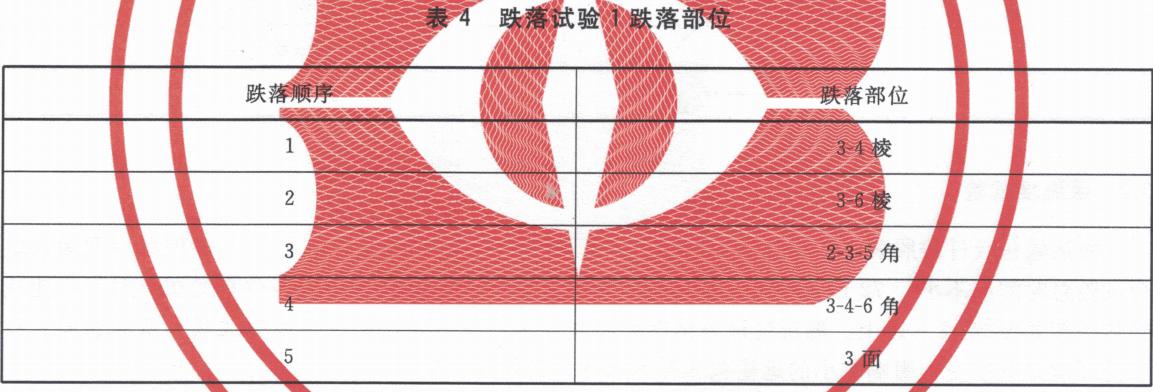

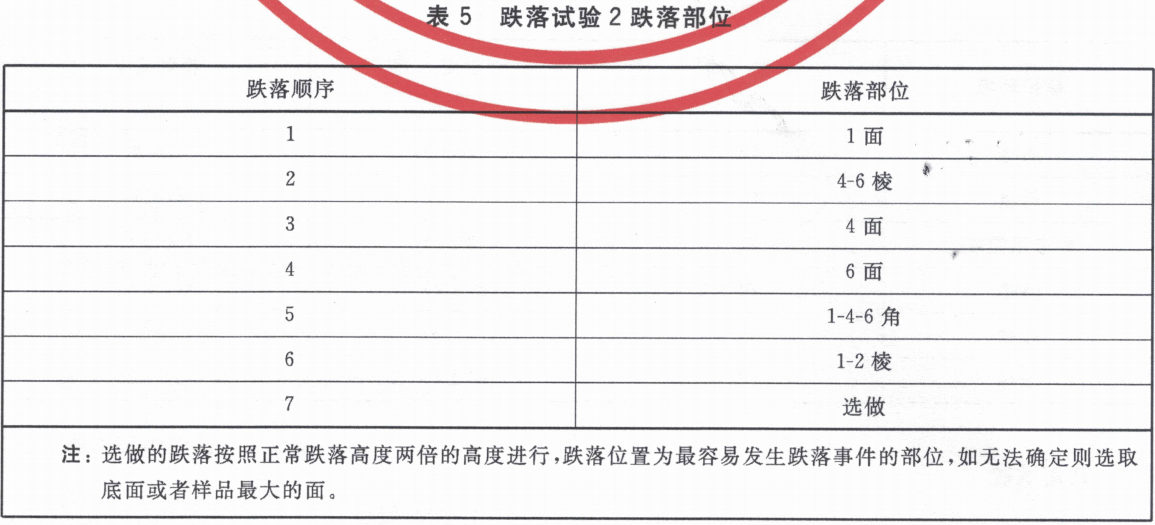

Test 2: Drop Test 1 and 2

The drop test height and sample testing location are shown in Tables 3 to 5. Raise the transportation packaging to the designated height and then freely fall and collide with the impact table according to the predetermined state.

Test 3: Stacking test

Place the transportation packaging flat on the base of the stacking test equipment, set the stacking pressure value, start the stacking test equipment, and press the transportation packaging evenly at a speed of 12.7mm/min on the upper panel of the equipment until the pressure reaches the set value. After holding for 1 hour, release the pressure.

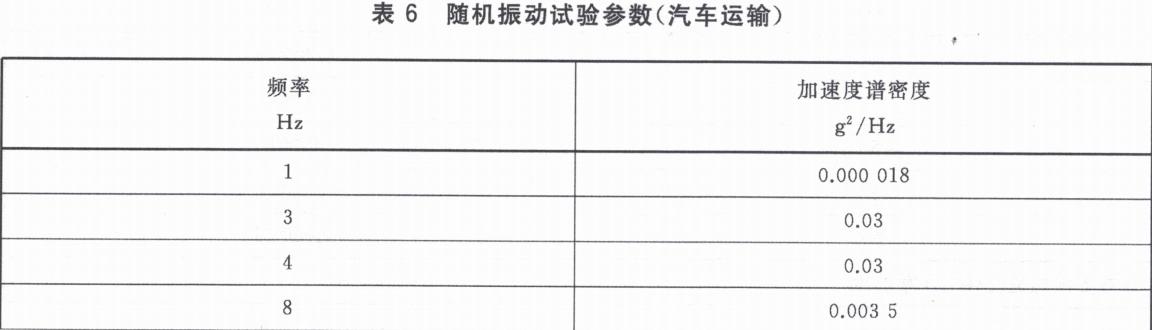

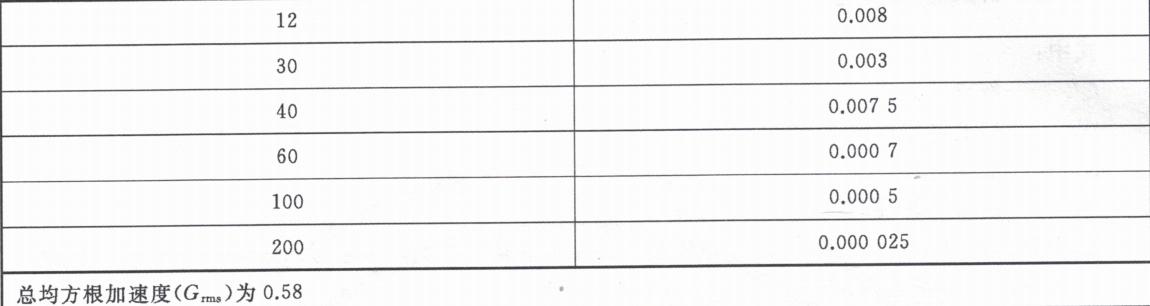

Experiment 4: Random vibration test

This experiment is mainly divided into three types of random vibration tests, namely simulated automobile transportation, simulated train transportation, and simulated aircraft transportation. The test parameters are shown in Tables 6, 7, and 8. The recommended test time for this experiment is 180 minutes, and the test time should be allocated to three types of random vibration tests based on actual transportation conditions. During the testing process, the transportation packaging is placed on the vertical vibration table of the vibration testing equipment in the actual transportation direction, usually without fixed placement. The sample is surrounded by a frame to ensure that the transportation packaging can move a certain distance without restraint in each horizontal direction but will not fall from the table.

Test 5: Constant frequency vibration test

The test time for fixed frequency vibration is 60 minutes, and all tests are completed on the vertical table of the vibration test equipment. 50% of the test time is conducted from the bottom down, and the remaining 50% is evenly distributed to other possible surfaces.

2、 The significance of transportation packaging testing:

1. Avoid insufficient, excessive or improper packaging;

2. Reduce the probability of damage during transportation due to packaging issues to ensure product value;

3. Reduce the cost of packaging materials to achieve the goal of reducing comprehensive production costs;

4. Meet packaging safety requirements;

5. Shorten packaging development time;

6. Improve customer satisfaction, reduce and eliminate claims disputes between buyers and sellers;

7. Make packaging more environmentally friendly, comply with national regulations, and enhance the corporate social responsibility image.

3、 Standard drafting unit:

4、 ORT transportation packaging testing capability:

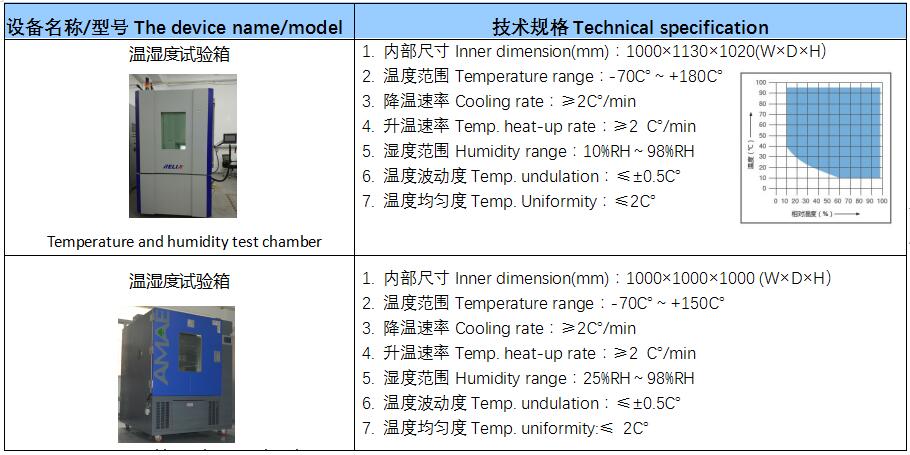

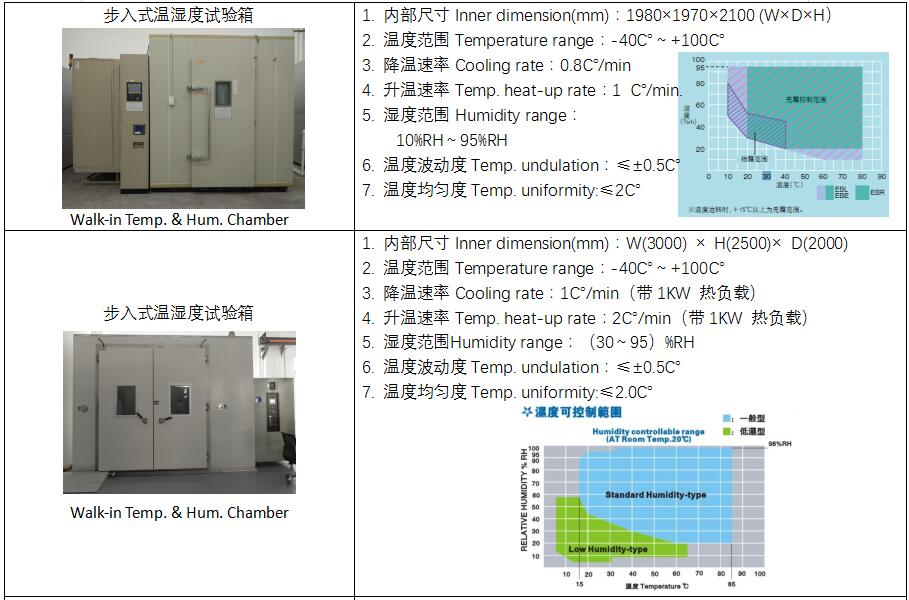

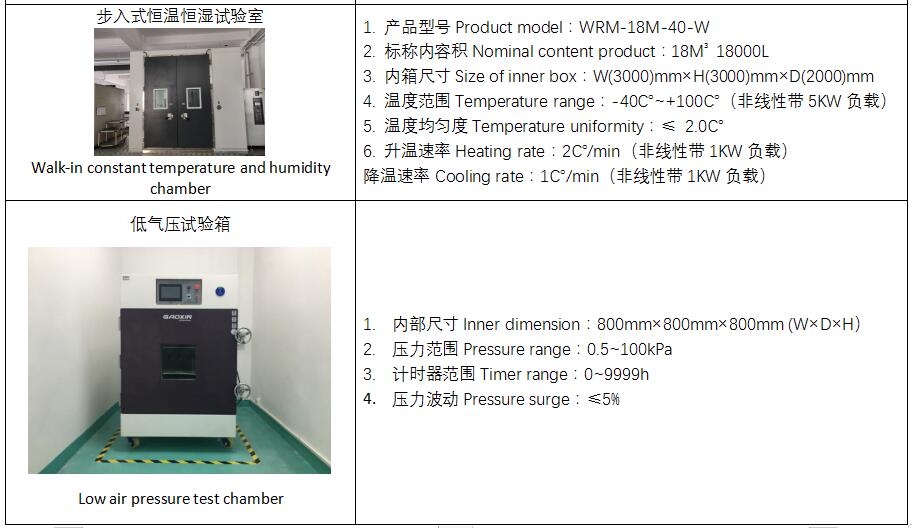

1. Environmental processing capacity parameters

2、Vibration test capability parameters

3、Drop Test Capability Parameters

4、Clamping test capability parameters

5、Horizontal impact/inclined impact test capability parameters

6、Packaging compression test capability parameters

7、Forklift Handling Test Capability Parameters

5、 ORT participated in drafting, published standards:

1. GB/T 35774-2017 'Specification for Performance Testing of Transport Packaging Components'

2. GB/T 4857.1-2019 'Basic Testing of Packaging, Transportation, and Packaging Components - Part 1: Marking Methods for Various Parts during Testing'

3. GB/T 4798.1-2019 'Classification of Environmental Conditions - Classification of Environmental Parameter Groups and Classification of Their Severity - Part 1: Storage'

4. GB/T 2421-2020 'Overview and Guidelines for Environmental Testing'

5. GB/T 2423.27-2020 'Environmental Testing - Part 2: Test Methods, Test Methods and Guidelines: Temperature/Low Pressure or Temperature/Humidity/Low Pressure Combined Tests'

6. GB/T 2423.51-2020 'Environmental Testing - Part 2: Test Methods - Test Ke: Flow Mixed Gas Corrosion Test'

7. GB/T 32065.8-2020 Marine Instruments - Environmental Testing Methods - Part 8: Temperature Change Test

8. GB/T 32065.10-2020 Marine Instruments - Environmental Testing Methods - Part 10: Salt Spray Test

9. GB/T 4797.9-2021 Classification of Environmental Conditions - Natural Environmental Conditions - Shock and Vibration Data Measured during Storage, Transportation, and Use

10. GB/T 2423.33-2021 Environmental Testing Part 2: Test Methods Test Kca: High Concentration Sulfur Dioxide Test

11. GB/T 2423.18-2021 Environmental Testing Part 2: Test Methods Test Kb: Salt Spray, Alternating (Sodium Chloride Solution)

12. NB/T 10279-2019 'Wet and Hot Environmental Conditions for Transmission and Transformation Equipment'

13. NB/T 10280-2019 'Wet and Hot Environmental Conditions and Technical Requirements for State Monitoring Devices Used in Power Grids'

14. YZ/T 0174-2020 Technical Requirements for Cold Chain Delivery Insulation Box

15. T/CPF 0012-2020 Guidelines for Testing Small Transport Packages for Express Delivery

16. T/CPF 0011-2020 Guidelines for Testing Electrical Transportation Packaging in E-commerce Logistics