1、 Basic information of the standard:

Standard Name: Technical Requirements for Cold Chain Delivery Insulation Box

Standard No.: YZ/T 0174-2020 (Postal Industry Standard of the People's Republic of China)

This standard was issued on December 18, 2020 and will be implemented on March 1, 2021.

This standard is proposed and under the jurisdiction of the National Postal Industry Standardization Technical Committee (SAC/TC 462), with the competent department being the National Postal Administration.

Standard scope: This document specifies the model, requirements, test methods, inspection rules, packaging, marking, transportation, and storage of cold chain delivery insulation boxes.

This document is applicable to the production, inspection, packaging, marking, transportation, and storage of insulation boxes other than pharmaceutical cold chains.

Test method:

1. Dimensions and deviations

Use calibrated measuring tools to measure the size and thickness of the box body, and use the arithmetic mean of the test results of 5 samples as the test result.

2. Physical performance

2.1. Compression resistance

The test should be conducted in accordance with the provisions of GB/T 4857.4-2008.

2.2 Impact resistance

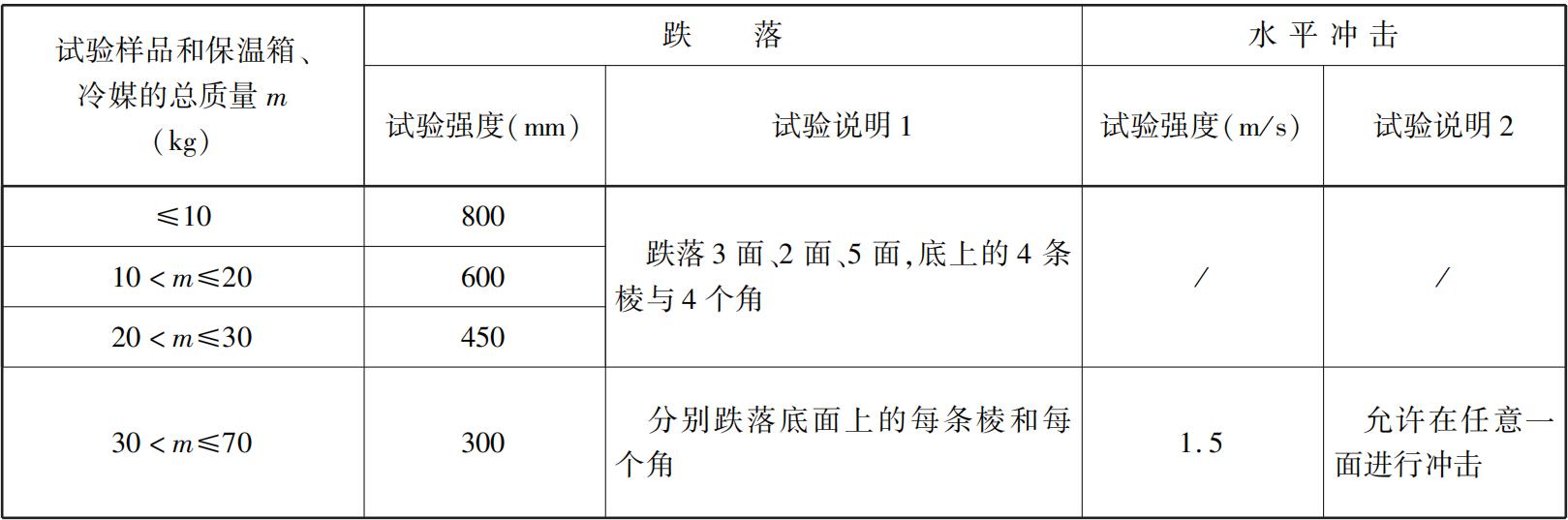

The goods with the maximum load capacity inside the box shall be tested in accordance with the provisions of GB/T 4857, 5-1992 and GB/T 4857.11-2005. The test requirements are shown in the table below:

2.3 Dust and waterproof measures

Conduct the test according to the provisions of GB/T 4208-2017.

3. Thermal insulation performance

3.1 Thermal conductivity

Conduct testing in accordance with the provisions of GB/T 10294-2008.

3.2. Insulation box thickness

Use calibrated measuring tools to measure the four walls of the box, and use the arithmetic mean of the test results of five samples as the test result.

3.3. Refrigerant

3.3.1 Phase transition temperature

Conduct the test according to the provisions of GB/T 19466.3, and immerse the probe of the temperature recorder used for verification into the refrigerant to detect the temperature changes and deviations during the phase change process of the refrigerant.

3.3.2 Phase change latent heat

Determine according to the provisions of GB/T 19466.3.

3.3.3. Six items of refrigerant RoHS

Determine according to the provisions of GB/T 26125-2011.

3.3.4 Material of container

Determine according to the provisions of GB/T 4806.7-2016.

3.3.5 Withstand voltage

According to the provisions of GB/T 4857.4-2008, the measurement requires a pressure of 2000Pa above a single refrigerant after freezing, and the test duration is 1 hour.

3.3.6 Resistance to deformation

Use calibrated measuring tools to measure the thickness and local protrusion size of the refrigerant before and after freezing, and compare the size changes before and after freezing.

3.4 Temperature monitoring equipment

The test method for temperature monitoring equipment shall be carried out in accordance with the requirements of 5.2 in WB/T 1097-2018.

4. Environmental requirements

4.1. Heavy metal testing shall be conducted in accordance with the provisions of SN/T 2046.

4.2. Solvent residue shall be tested in accordance with the provisions of GB/T 10004-2008.

4.3. Odor evaluation shall be tested in accordance with the provisions of GB/T 35773.

5. Reusable times

Develop a testing plan in accordance with the requirements of Chapter 5 and Chapter 6 of GB/T 16716.3-2018. The user shall track and verify the product in actual scenarios, and record the number of repeated uses of the product. The arithmetic mean of the test results of 50 samples shall be used as the test result.

2、 Standard drafting unit:

3、 The Role and Scope of Cold Chain

For perishable food, the refrigeration temperature is monitored through the cold chain to ensure its excellent quality and safe consumption. The cold chain lies in the ability to control the temperature of perishable products, ensure their safety in use, and ensure that consumers still have good quality when purchasing products. If the temperature control is not accurate enough, it will lead to a series of quality degradation of the product. In addition to changes in general product characteristics, it also includes changes in organizational structure, color, damage during collision and extrusion, and microbial reproduction. Every link in the cold chain, from the moment the product is picked to the moment it is sold, requires participation in control. Every link in the chain can go wrong and cause the cold chain to break, either on the platform of the warehouse, during transportation, during storage, or in retail supermarkets, which can easily cause problems. If a link breaks, it will affect the demand of the final consumer.

The main scope of cold chain transportation products:

Primary agricultural products: vegetables, fruits; Meat, poultry, eggs; Aquatic products; Flower products.

Processed food: frozen food; Packaged cooked food such as poultry, meat, and aquatic products; Ice cream and dairy products; Fast food ingredients.

Special commodities: biological products, pharmaceuticals

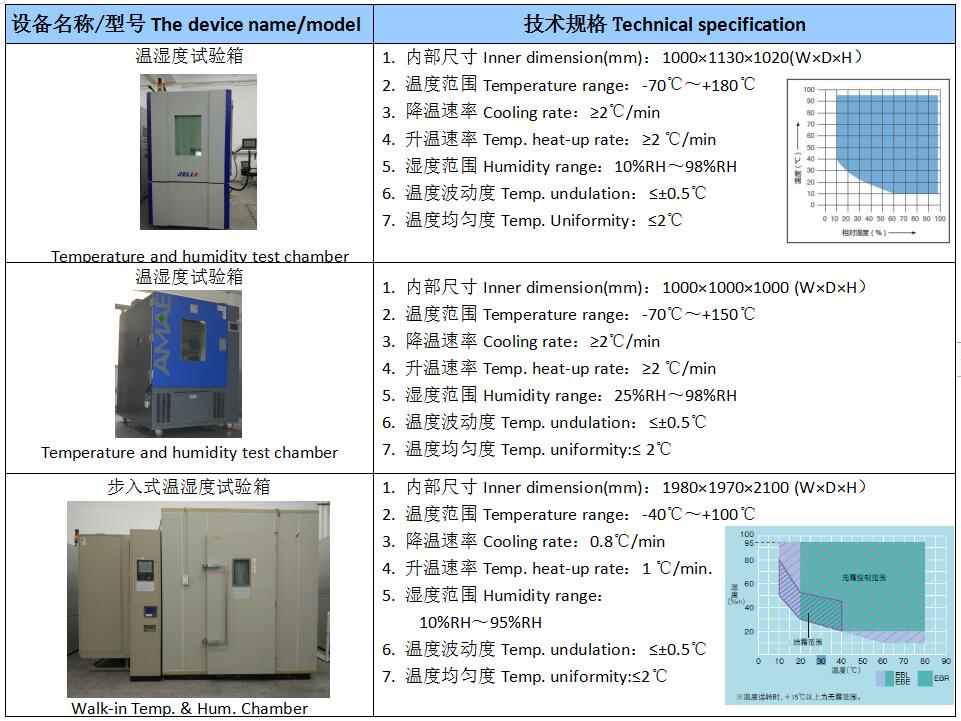

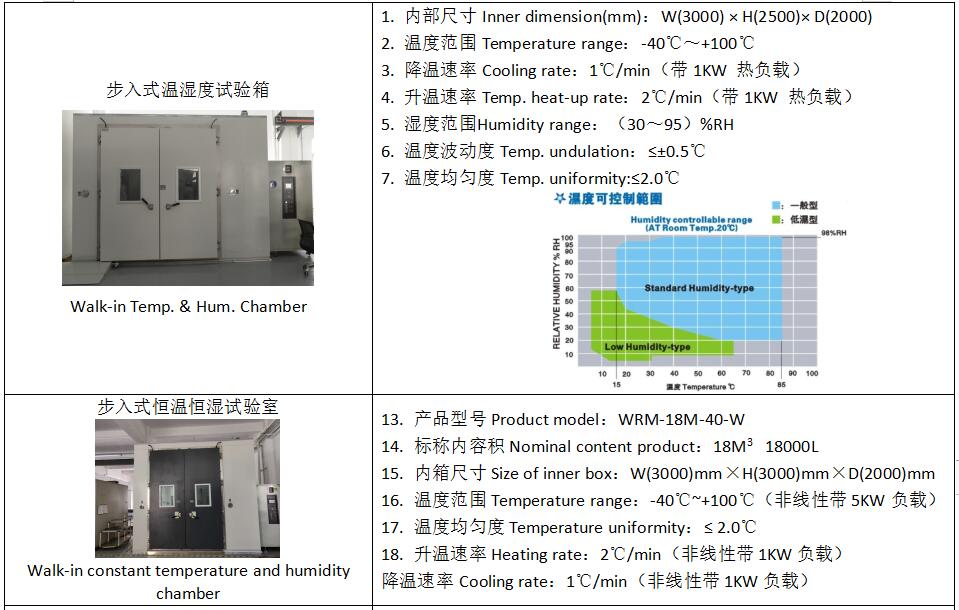

4、 ORT Packaging Testing Capability

1. Environmental processing capacity parameters

2、Vibration test capability parameters

3、Drop Test Capability Parameters

4、Clamping test capability parameters

5、Horizontal impact/inclined impact test capability parameters

6、Packaging compression test capability parameters

7、Forklift Handling Test Capability Parameters

5、 ORT participated in drafting and published standards:

1. GB/T 35774-2017 'Specification for Performance Testing of Transport Packaging Components'

2. GB/T 4857.1-2019 'Basic Testing of Packaging, Transportation, and Packaging Components - Part 1: Marking Methods for Various Parts during Testing'

3. GB/T 4798.1-2019 'Classification of Environmental Conditions - Classification of Environmental Parameter Groups and Classification of Their Severity - Part 1: Storage'

4. GB/T 2421-2020 'Overview and Guidelines for Environmental Testing'

5. GB/T 2423.27-2020 'Environmental Testing - Part 2: Test Methods, Test Methods and Guidelines: Temperature/Low Pressure or Temperature/Humidity/Low Pressure Combined Tests'

6. GB/T 2423.51-2020 'Environmental Testing - Part 2: Test Methods - Test Ke: Flow Mixed Gas Corrosion Test'

7. GB/T 32065.8-2020 Marine Instruments - Environmental Testing Methods - Part 8: Temperature Change Test

8. GB/T 32065.10-2020 Marine Instruments - Environmental Testing Methods - Part 10: Salt Spray Test

9. GB/T 4797.9-2021 Classification of Environmental Conditions - Natural Environmental Conditions - Shock and Vibration Data Measured during Storage, Transportation, and Use

10. GB/T 2423.33-2021 Environmental Testing Part 2: Test Methods Test Kca: High Concentration Sulfur Dioxide Test

11. GB/T 2423.18-2021 Environmental Testing Part 2: Test Methods Test Kb: Salt Spray, Alternating (Sodium Chloride Solution)

12. NB/T 10279-2019 'Wet and Hot Environmental Conditions for Transmission and Transformation Equipment'

13. NB/T 10280-2019 'Wet and Hot Environmental Conditions and Technical Requirements for State Monitoring Devices Used in Power Grids'

14. YZ/T 0174-2020 Technical Requirements for Cold Chain Delivery Insulation Box

15. T/CPF 0012-2020 Guidelines for Testing Small Transport Packages for Express Delivery

16. T/CPF 0011-2020 Guidelines for Testing Electrical Transportation Packaging in E-commerce Logistics