3.4 Mechanical active substance testing

Mechanical active substances mainly refer to the general term for particulate matter that can be suspended in the air, such as dust, sand, cotton wool, and small branches. Due to the particularly complex causes of sand and dust in nature, it is difficult to conduct actual simulations. Therefore, the main purpose of mechanical active substance testing is to verify sealing performance, rather than simulating the actual environment for validation testing.

The content of sand and dust in the atmospheric environment varies depending on the region. With the increase of human development, dust storms and haze may lead to product failure. In addition, substances such as cotton wool in the actual human living environment can further lead to failure. Simulated sand and dust environments are crucial for products, especially outdoor products, long-term continuous working equipment, and products placed in enclosed spaces.

failure mechanism

Sand and dust can fall to the ground due to their own gravitational stress, or be blown into gaps and invade the interior of objects due to the influence of wind.

Possible conditions for sand and dust intrusion:

Brought in by forced air circulation, such as heat dissipation;

Brought in by the thermal motion of air;

Pressure difference suction caused by temperature changes;

The wind blows in.

Dust may cause the following failures:

Changes in electrical performance of equipment;

Contact faults, changes in contact resistance, etc;

Reduce thermal conductivity;

Increased resistance or jamming of moving parts such as bearings;

Surface wear;

Contamination of optical surfaces and lubricant contamination;

Blockage of ventilation pipes, sleeves, conduits, filters, and holes;

Test standards

The sand and dust test mainly refers to the IEC60068-2-68 (GB/T2423.37) MIL-STD-810 Method 510IEC 60529 (GB 4208) EIA-364-50AEIA-364-91A standard. The introduction of the US military standard test method is quite detailed and can be used as a reference book. The specific method for civilian products is mainly IEC.

At present, it is recommended to use the IEC 60529 standard for dust protection levels of IP4X, IP5X, and IP6X for civilian use. The following is an introduction to the testing methods for IP protection.

Overview of IP Protection Level Representation Methods

The level of protection is often expressed as an IP followed by two numbers, which are used to specify the level of protection.

The first digit indicates the range of dust resistance of the device, or the degree to which people are protected from harm in a sealed environment. Represents the level of preventing solid foreign objects from entering, with a maximum level of 6;

The second digit indicates the degree of waterproofing of the equipment. Represents the level of water prevention, with a maximum level of 8.

Representation of IP protection level

The first digit after IP: Dust level

数字 | 防护范围 | 说明 |

0 | 无防护 | 对外界的人或物无特殊的防护 |

1 | 防止直径大于50mm的固体外物侵入 | 防止人体(如手掌)因意外而接触到电器内部的零件,防止较大尺寸(直径大于50mm)的外物侵入 |

2 | 防止直径大于12.5mm的固体外物侵入 | 防止人的手指接触到电器内部的零件,防止中等尺寸(直径大于12.5mm)的外物侵入 |

3 | 防止直径大于2.5mm的固体外物侵入 | 防止直径或厚度大于2.5mm的工具、电线及类似的小型外物侵入而接触到电器内部的零件 |

4 | 防止直径大于1.0mm的固体外物侵入 | 防止直径或厚度大于1.0mm的工具、电线及类似的小型外物侵入而接触到电器内部的零件 |

5 | 防止外物及灰尘 | 完全防止外物侵入,虽不能完全防止灰尘侵入,但灰尘的侵入量不会影响电器的正常运作 |

6 | 防止外物及灰尘 | 完全防止外物及灰尘侵入 |

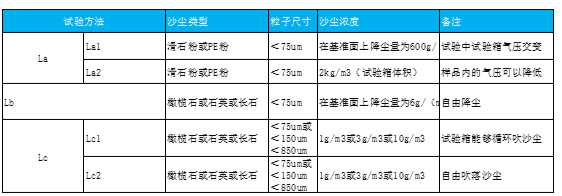

The following table shows the test methods for IP dust prevention