1、 Basic information of the standard:

Standard name: Environmental testing Part 2: Test methods Test Kca: High concentration sulfur dioxide test

Standard number: GB/T 2423.33-2021

This standard replaces GB/T 2423.33-2005 'Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods - Test Kca: High Concentration Sulfur Dioxide Test'

This standard was issued on May 21, 2021 and will be implemented on December 1, 2021.

This standard is under the jurisdiction of TC8 (National Technical Committee for Standardization of Environmental Conditions and Environmental Testing of Electrical and Electronic Products) and is implemented by TC8/SC2 (Climate and Environmental Testing Branch of National Technical Committee for Standardization of Environmental Conditions and Environmental Testing of Electrical and Electronic Products). The competent department is the National Standardization Management Committee.

Scope of this standard:

This standard specifies the general conditions and methods for testing samples in alternating climates containing high concentrations of sulfur dioxide in condensed water, especially for sulfur dioxide concentrations not included in GB/T 9789-2008, in order to obtain comparable test results when tested in different laboratories.

This standard is applicable to determining the suitability of products and their materials for use under chemical corrosive environmental conditions.

The content of this standard does not include sample shape, sample preparation, and analysis and evaluation of test results. Regarding these regulations, relevant standards can be consulted or negotiated based on specific circumstances.

This test cannot be directly used for comparison of corrosion resistance unless the application environment of the anti-corrosion system is similar. Due to the significant differences between corrosion test conditions and actual application conditions, the corrosion process and mechanism are different.

Test method:

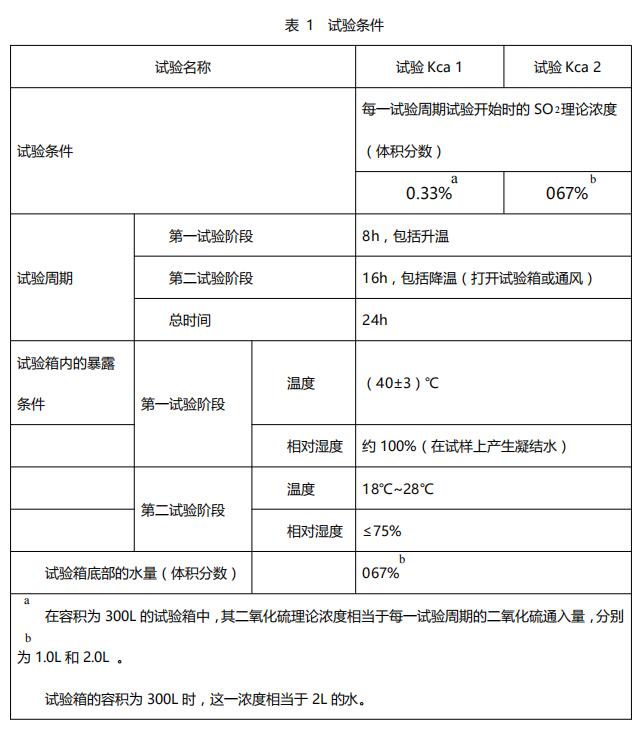

Test conditions

The sample should be placed in the test box without packaging, without power, in a 'ready for use' state, or in a state specified by relevant specifications.

The test conditions listed in Table 1 are partially different from those in GB/T 9789-2008. However, when conducting experiments, it is still necessary to consider 6.1, 6.2, and 6.4 in GB/T 9789-2008.

Note: At the beginning of the first experimental stage, most of the sulfur dioxide gas introduced quickly dissolves into the water at the bottom of the test chamber. Therefore, the effective concentration of sulfur dioxide in the gas space is about one-seventh of the theoretical concentration. During the first experimental stage, the initial concentration did not remain constant, but first sharply and then slowly decreased.

At the beginning of the second stage of the test, the heating should be stopped and the test chamber should be opened or ventilated. After approximately 1.5 hours, the test conditions given in Table 1 should be met.

Test time

Unless otherwise specified, the test cycle should be prioritized from the following cycles: 1, 2, 5, 10, 15, or 20 cycles, with one cycle lasting 24 hours. If corrosion damage has reached an unacceptable level during the test, i.e. the appearance or function of the sample has been damaged, the test can be terminated.

Usually, the water and sulfur dioxide gas in the test system should be replaced at the end of each cycle, and the replacement should not interfere with the sample.

Intermediate detection

The relevant regulations can stipulate that electrical and/or other performance tests should be carried out on the specimens in the test chamber within 3 hours before the end of each cycle during the testing period. After performance testing, it is allowed to open the test box to collect and place samples. The opening time should be as short as possible and should be completed within 0.5 hours before heating up.

2、 Failure mechanism

1. Strong reducing agent, with strong corrosion resistance to general non-metallic surface coatings and non-metallic materials; The corrosion on the surface of metal materials is caused by chemical reactions between the oxide layer and protective layer of the metal containing chloride ions and the internal metal.

2. It forms strong acids and has strong corrosion ability on general non-metallic surface coatings and non-metallic materials.

3. The generated sulfite and sulfuric acid directly damage the oxide film on the surface of metal products, causing various corrosion effects such as electrochemical corrosion.

3、 ORT high concentration sulfur dioxide test capability:

4、 Standard drafting unit:

5、ORT participated in drafting and published standards:

1. GB/T 35774-2017 'Specification for Performance Testing of Transport Packaging Components'

2. GB/T 4857.1-2019 'Basic Testing of Packaging, Transportation, and Packaging Components - Part 1: Marking Methods for Various Parts during Testing'

3. GB/T 4798.1-2019 'Classification of Environmental Conditions - Classification of Environmental Parameter Groups and Classification of Their Severity - Part 1: Storage'

4. GB/T 2421-2020 'Overview and Guidelines for Environmental Testing'

5. GB/T 2423.27-2020 'Environmental Testing - Part 2: Test Methods, Test Methods and Guidelines: Temperature/Low Pressure or Temperature/Humidity/Low Pressure Combined Tests'

6. GB/T 2423.51-2020 'Environmental Testing - Part 2: Test Methods - Test Ke: Flow Mixed Gas Corrosion Test'

7. GB/T 32065.8-2020 Marine Instruments - Environmental Testing Methods - Part 8: Temperature Change Test

8. GB/T 32065.10-2020 Marine Instruments - Environmental Testing Methods - Part 10: Salt Spray Test

9. GB/T 4797.9-2021 Classification of Environmental Conditions - Natural Environmental Conditions - Shock and Vibration Data Measured during Storage, Transportation, and Use

10. GB/T 2423.33-2021 Environmental Testing Part 2: Test Methods Test Kca: High Concentration Sulfur Dioxide Test

11. GB/T 2423.18-2021 Environmental Testing Part 2: Test Methods Test Kb: Salt Spray, Alternating (Sodium Chloride Solution)

12. NB/T 10279-2019 'Wet and Hot Environmental Conditions for Transmission and Transformation Equipment'

13. NB/T 10280-2019 'Wet and Hot Environmental Conditions and Technical Requirements for State Monitoring Devices Used in Power Grids'

14. YZ/T 0174-2020 Technical Requirements for Cold Chain Delivery Insulation Box

15. T/CPF 0012-2020 Guidelines for Testing Small Transport Packages for Express Delivery

16. T/CPF 0011-2020 Guidelines for Testing Electrical Transportation Packaging in E-commerce Logistics