1、 Basic information of the standard:

Standard name: Environmental testing methods for marine instruments Part 8: Temperature change test

Standard number: GB/T 32065.8-2020

Centralized unit: National Marine Standardization Technical Committee

Executive unit: National Marine Standardization Technical Committee

Department in charge: Ministry of Natural Resources (Marine)

This standard was issued on November 19, 2020 and implemented on June 1, 2021.

Scope of this standard:

This standard specifies the test requirements, selection of test methods, stepped temperature changes, rapid temperature changes, and related information for temperature change testing of marine instruments.

This standard is applicable to assessing or determining the adaptability of marine instruments to temperature changes, and can also serve as a reference for temperature change environmental testing of their components and components.

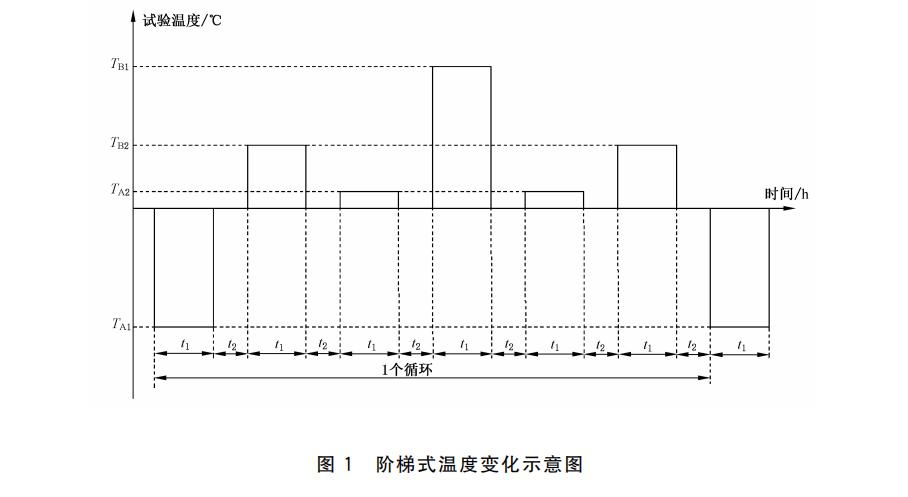

Test Method 1: Stepwise Temperature Change

1. The test samples should be placed directly in a low-temperature test chamber (chamber) that has stabilized to TA1 without packaging, power supply, and ready for operation. Then, the work should be started and the exposure duration specified in 3.3.2 should be maintained. During this period, the test samples should remain in operation.

2. Take the test sample from the low-temperature test chamber (chamber) and directly convert it to a high-temperature test chamber (chamber) that has stabilized to TB2 (20 ℃) under standard atmospheric conditions, while maintaining the exposure duration specified in 3.3.2. During this period, adjust the temperature inside the low-temperature test chamber (chamber) from TA1 to TA2 (2 ℃).

3. Remove the test sample from the high-temperature test chamber (chamber) and directly convert it to a low-temperature test chamber (chamber) that has stabilized to TA2 (2 ℃) under standard atmospheric conditions, while maintaining the exposure duration specified in 3.3.2. During this period, adjust the temperature inside the high-temperature test chamber (chamber) from TB2 (20 ℃) to TB1.

4. Take the test sample from the low-temperature test chamber (chamber) and directly convert it to a high-temperature test chamber (chamber) that has stabilized to TB1 under standard atmospheric conditions, while maintaining the exposure duration specified in 3.3.2.

5. Remove the test sample from the high-temperature test chamber (chamber) and directly convert it to a low-temperature test chamber (chamber) that has stabilized to TA2 (2 ℃) under standard atmospheric conditions, while maintaining the exposure duration specified in 3.3.2. During this period, adjust the temperature inside the high-temperature test chamber (chamber) from TB1 to TB2 (20 ℃).

6. Take the test sample from the low-temperature test chamber (chamber) and directly convert it to a high-temperature test chamber (chamber) that has stabilized to TB2 (20 ℃) under standard atmospheric conditions, while maintaining the exposure duration specified in 3.3.2.

7. Steps 5.3.1 to 5.3.6 above represent a complete cycle of stepped temperature changes, as shown in Figure 1.

8. Continue to conduct subsequent cycle tests according to the number of cycles specified in 3.3.4.

9. After the end of the last cycle, the test sample should be taken out of the high-temperature chamber and restored.

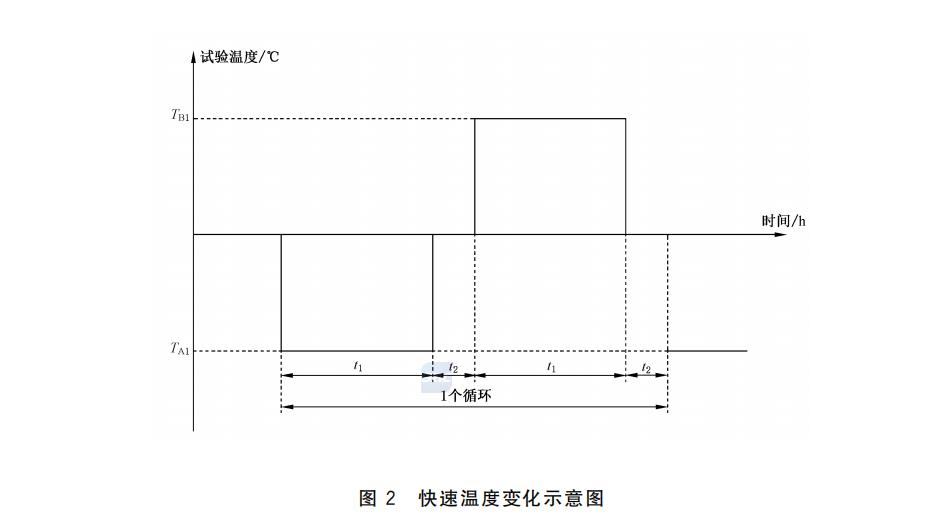

Test Method 2: Rapid Temperature Change

1. The test samples should be placed directly in a low-temperature test chamber (chamber) that has stabilized to TA1 without packaging, power supply, and ready for operation. Then, the work should be started and the exposure duration specified in 3.3.2 should be maintained. During this period, the test samples should remain in operation.

2. Take the test sample from the low-temperature test chamber (chamber) and directly convert it to a high-temperature test chamber (chamber) that has stabilized to TB1 (20 ℃) under standard atmospheric conditions, while maintaining the exposure duration specified in 3.3.2.

3. Steps 6.3.1 to 6.3.2 above represent a complete cycle of rapid temperature changes, as shown in Figure 2.

4. Continue to conduct subsequent cycle tests according to the number of cycles specified in 3.3.4.

5. After the end of the last cycle, the test sample should be taken out of the high-temperature chamber and restored.

2、 Failure modes of temperature changes:

At present, it is known that marine instruments can withstand the influence of climate and environment during storage, transportation, and use, leading to various malfunctions and failures. Years of statistical data have shown that temperature factors account for up to 35% of malfunctions in marine instrument usage environments. Especially in the conversion stage of water meters in different areas above and below water, they are more susceptible to temperature effects, which can lead to malfunctions. Therefore, conducting reasonable temperature change tests can more realistically reflect the environment and failure modes encountered by the instrument and equipment, and more fully stimulate the hidden defects, faults, and failures of the product.

The temperature change usually has a more severe impact on the part near the outer surface of the instrument. The farther away from the surface, the slower the temperature change, and the relatively small impact. Sharp temperature changes may temporarily or permanently affect instrument performance. The following are examples of possible malfunctions that may occur when the instrument is exposed to temperature changing environments.

1. Typical physical effects

Fragmentation of glass containers and optical instruments; Clamping or loosening of moving parts; The shrinkage or expansion rate and induced strain rate of different materials are different; Deformation or rupture of components; Surface coating cracking; Leakage of sealed compartments; Insulation protection failure, etc.

2. Typical chemical effects

Separation of chemical components; Chemical reagent protection failure, etc.

3. Typical electrical effects

Changes in electrical and electronic components; Electronic or mechanical malfunctions caused by rapid condensation or frost formation; Excessive static electricity, etc.

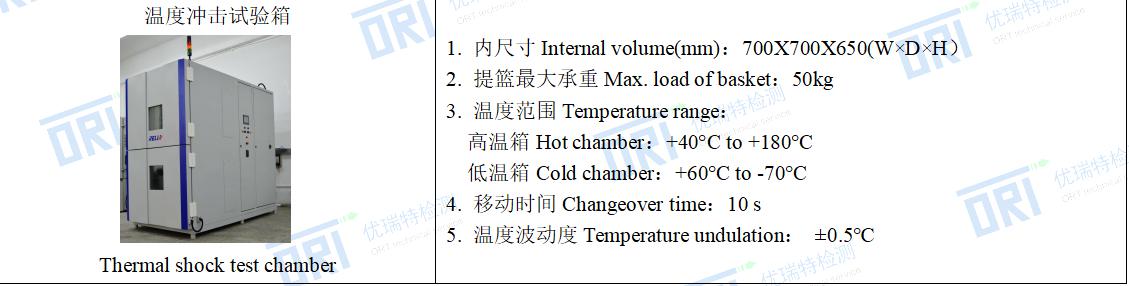

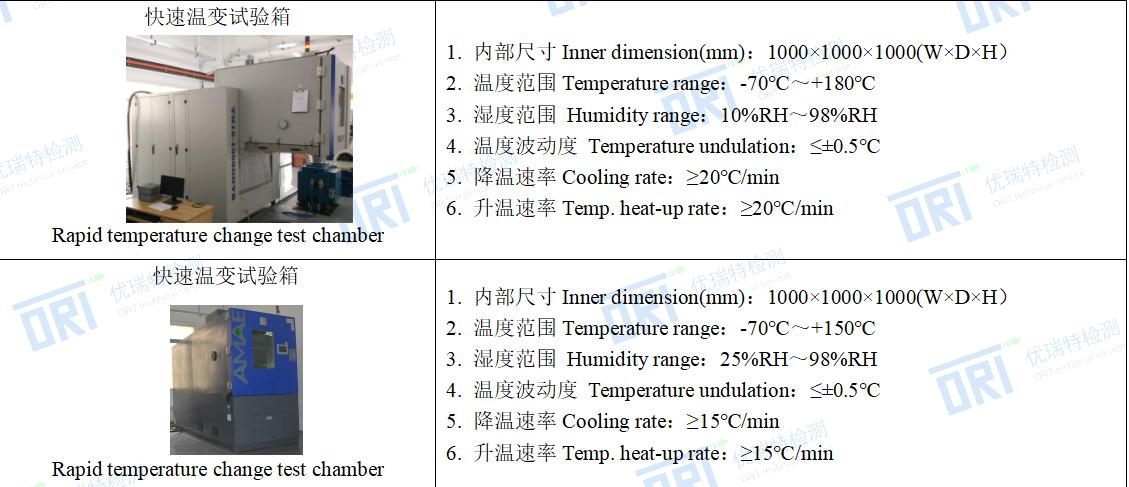

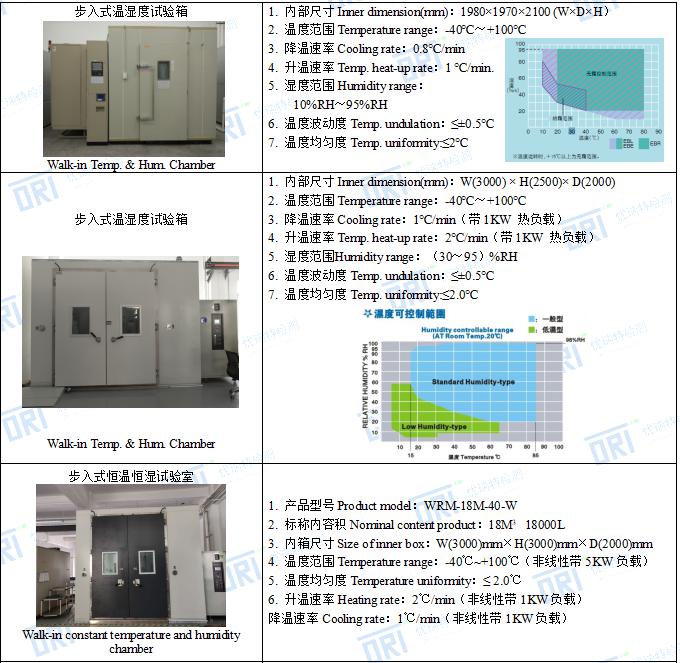

4、 ORT temperature change test capability:

五、标准起草单位:

6、ORT participated in drafting and published standards:

1. GB/T 35774-2017 'Specification for Performance Testing of Transport Packaging Components'

2. GB/T 4857.1-2019 'Basic Testing of Packaging, Transportation, and Packaging Components - Part 1: Marking Methods for Various Parts during Testing'

3. GB/T 4798.1-2019 'Classification of Environmental Conditions - Classification of Environmental Parameter Groups and Classification of Their Severity - Part 1: Storage'

4. GB/T 2421-2020 'Overview and Guidelines for Environmental Testing'

5. GB/T 2423.27-2020 'Environmental Testing - Part 2: Test Methods, Test Methods and Guidelines: Temperature/Low Pressure or Temperature/Humidity/Low Pressure Combined Tests'

6. GB/T 2423.51-2020 'Environmental Testing - Part 2: Test Methods - Test Ke: Flow Mixed Gas Corrosion Test'

7. GB/T 32065.8-2020 Marine Instruments - Environmental Testing Methods - Part 8: Temperature Change Test

8. GB/T 32065.10-2020 Marine Instruments - Environmental Testing Methods - Part 10: Salt Spray Test

9. GB/T 4797.9-2021 Classification of Environmental Conditions - Natural Environmental Conditions - Shock and Vibration Data Measured during Storage, Transportation, and Use

10. GB/T 2423.33-2021 Environmental Testing Part 2: Test Methods Test Kca: High Concentration Sulfur Dioxide Test

11. GB/T 2423.18-2021 Environmental Testing Part 2: Test Methods Test Kb: Salt Spray, Alternating (Sodium Chloride Solution)

12. NB/T 10279-2019 'Wet and Hot Environmental Conditions for Transmission and Transformation Equipment'

13. NB/T 10280-2019 'Wet and Hot Environmental Conditions and Technical Requirements for State Monitoring Devices Used in Power Grids'

14. YZ/T 0174-2020 Technical Requirements for Cold Chain Delivery Insulation Box

15. T/CPF 0012-2020 Guidelines for Testing Small Transport Packages for Express Delivery

16. T/CPF 0011-2020 Guidelines for Testing Electrical Transportation Packaging in E-commerce Logistics