Lithium batteries are dangerous goods that require professional packaging, specialized hazard labels, and specialized regulations. Possible issues with lithium battery packaging:

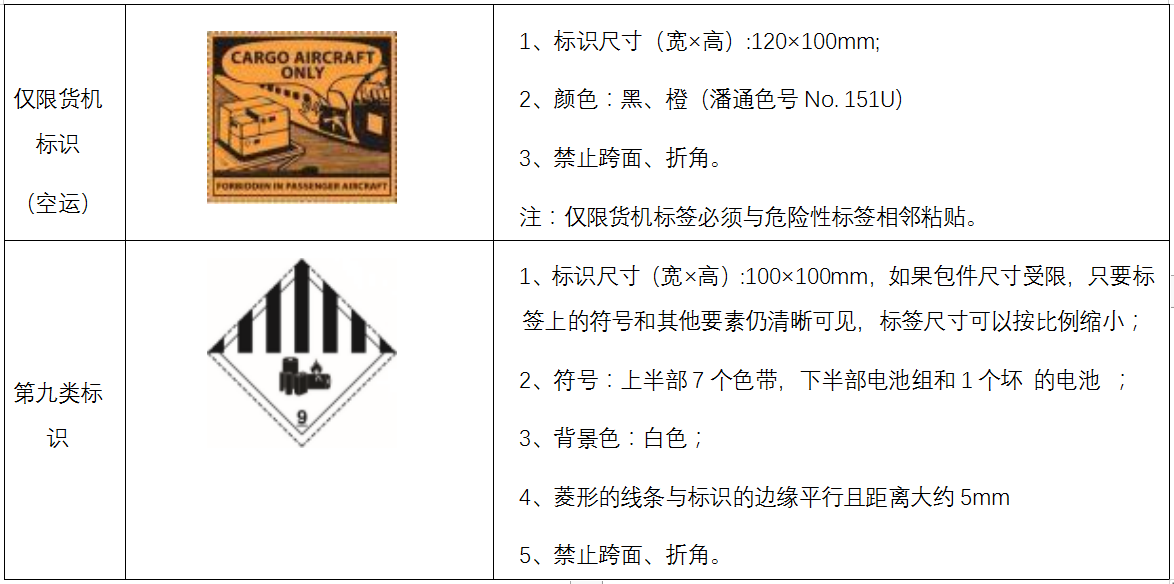

1. High safety risk, lithium batteries are classified as Class 9 hazardous materials by the United Nations (UN), and may cause short circuits, fires, and explosions during transportation due to vibration and impact.

2. Lithium batteries should comply with relevant regulations on dangerous goods during domestic and international transportation, and there are requirements for packaging specifications, labeling, testing, and other aspects of lithium batteries for different transportation methods.

3. The use of non compliant packaging can lead to risks such as loss of goods, casualties, and significant fines from regulatory authorities.

一、 Classification of lithium batteries

According to international regulations such as the United Nations Recommendation on the Transport of Dangerous Goods, the International Maritime Dangerous Goods Code, and the International Civil Aviation Organization Technical Rules for the Safe Transport of Dangerous Goods by Air, lithium batteries belong to category 9 miscellaneous dangerous goods (miscellaneous hazardous substances and items, including environmentally hazardous substances), with UN numbers covering UN3090, UN3091, UN3480, and UN3481. In the United Nations' Model Regulations and Recommendations on the Transport of Dangerous Goods (TDG), the classification of lithium battery transportation systems is as follows:

UN Number | PROPER SHIPPING NAME | Hazard Class |

3480 | Lithium ion battery pack (including lithium-ion polymer batteries) - rechargeable | 9 |

3481 | Lithium ion battery pack installed in the device (including lithium ion polymer batteries) | 9 |

3481 | Lithium ion battery pack packaged with equipment (including lithium ion polymer batteries) | 9 |

3090 | Lithium metal battery pack (including lithium alloy batteries) - non rechargeable | 9 |

3091 | Lithium metal battery pack installed in the device (including lithium alloy batteries) | 9 |

3091 | Lithium metal battery pack packaged with equipment (including lithium alloy batteries) | 9 |

3171 | Battery powered vehicles | 9 |

3536 | Lithium battery pack installed in freight equipment | 9 |

2、 Requirements for lithium battery packaging

2.1 Air Transport Requirements

At present, the International Air Transport Association (IATA) has officially released the latest version of the IATA DGR for the transportation of dangerous goods by air, which will be implemented in January 2022.

Lithium ion batteries shall be packaged in compliance with the packaging provisions 965-967 of the IATA Dangerous Goods Regulations.

Lithium metal batteries shall be packaged in compliance with the packaging provisions 968-970 of the IATA Dangerous Goods Regulations.

To ensure the safety of lithium battery transportation, the International Aviation Association (IATA) has made clear provisions in the Dangerous Goods Regulations (DGR) for air transportation. Maritime transportation also needs to comply with the relevant provisions of the International Maritime Dangerous Goods Code (IMDG) designated by the International Maritime Organization.

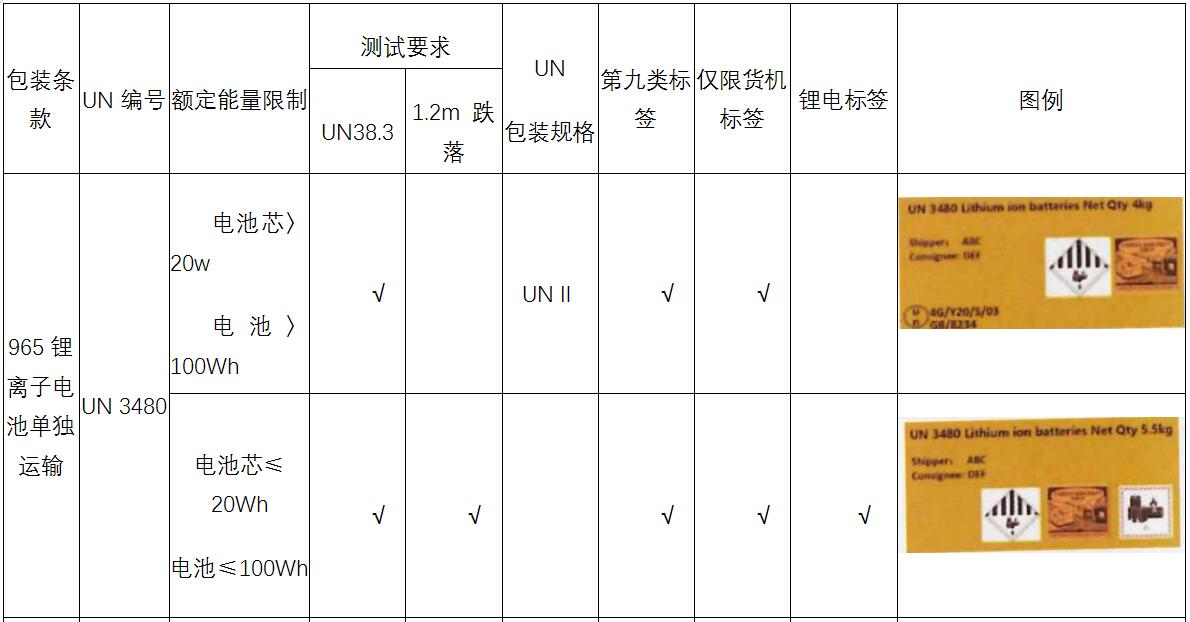

Requirements for packaging terms of air transport lithium-ion batteries:

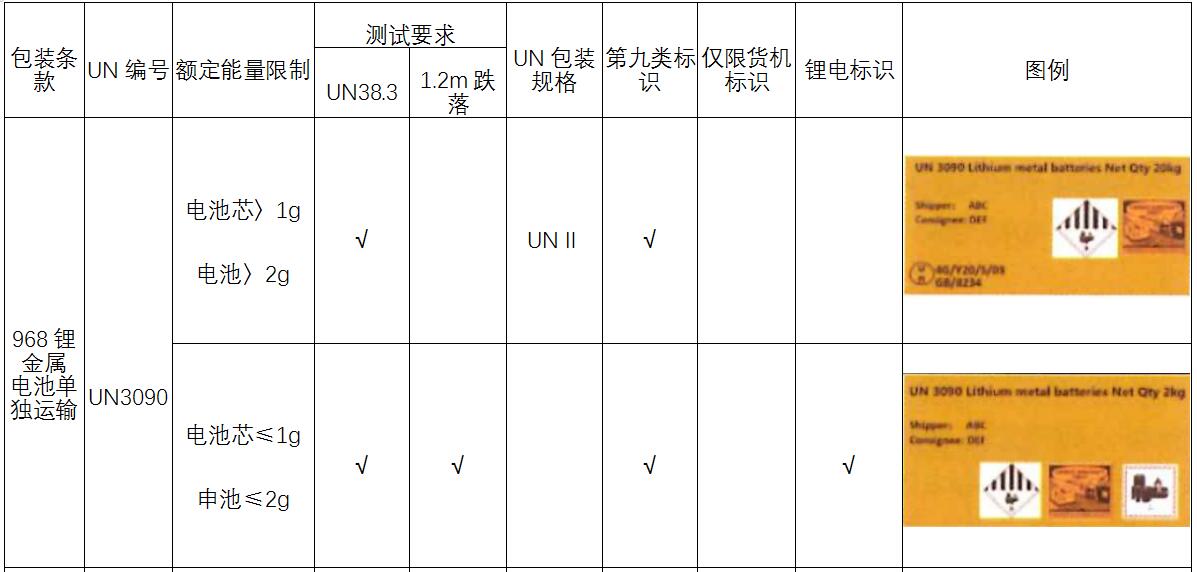

Requirements for packaging terms of lithium metal batteries for air transportation:

2.2 Maritime Requirements

The International Maritime Dangerous Goods Code (IMDG Code) is the most important rule for the transportation of packaged dangerous goods by sea, playing an important role in ensuring the safe transportation of packaged dangerous goods on board ships and preventing marine environmental pollution. According to Resolution MSC.477 (102) adopted at the 102nd meeting of the Maritime Safety Committee (MSC) of the International Maritime Organization, the IMDG Rules 40-20 amendments have made significant revisions to the classification, packaging, marking and marking of dangerous goods, and will be enforced from June 1, 2022.

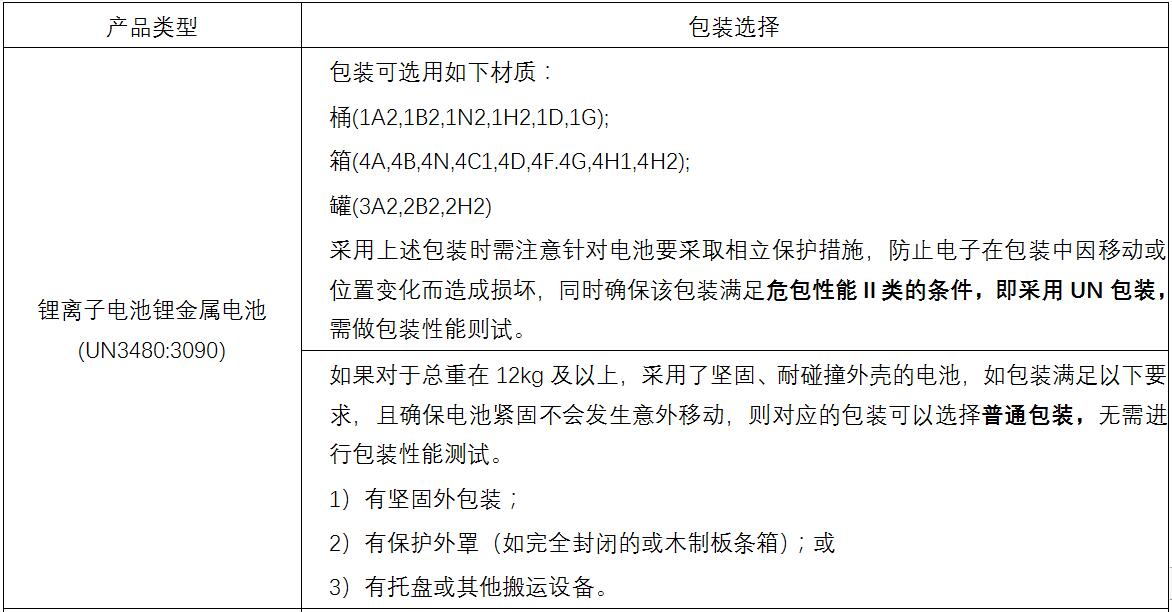

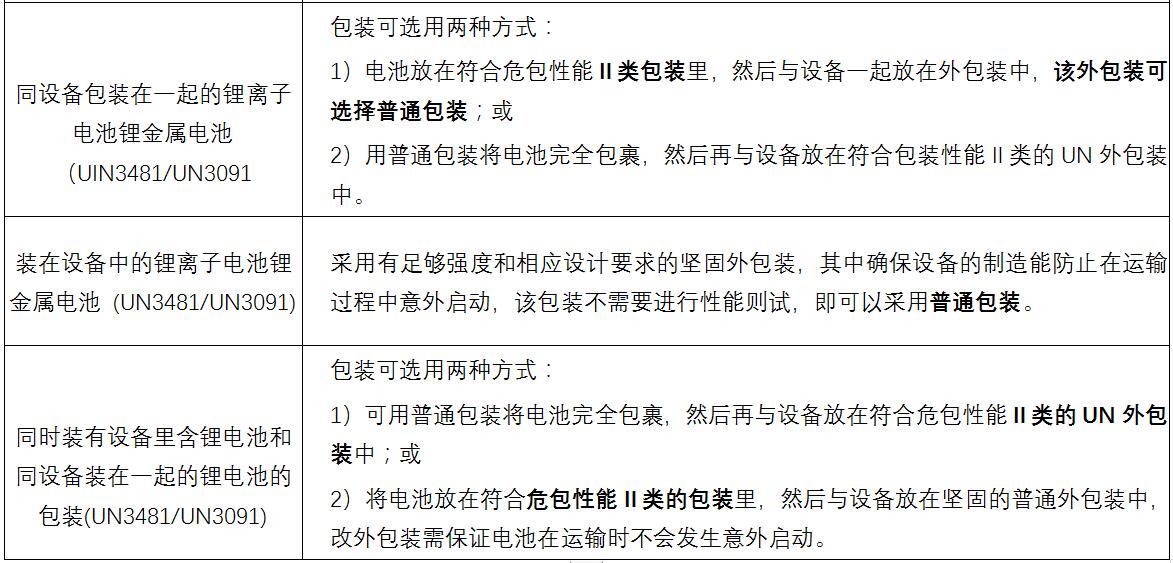

The compliant packaging of lithium batteries in the international shipping phase is based on the latest version of the IMDG Maritime Dangerous Goods Regulations (40-20 versions) for the use requirements of lithium battery packaging. Please refer to the packaging guidelines P903 for specific requirements.

Shipping lithium battery packaging requirements:

*The content marked is a new packaging form added to the packaging guideline P903 in the latest version of IMDG code (version 40-20), specifically targeting packaging that includes both lithium batteries packaged with the device and lithium batteries packaged inside the device.

2.3 Export Document Requirements

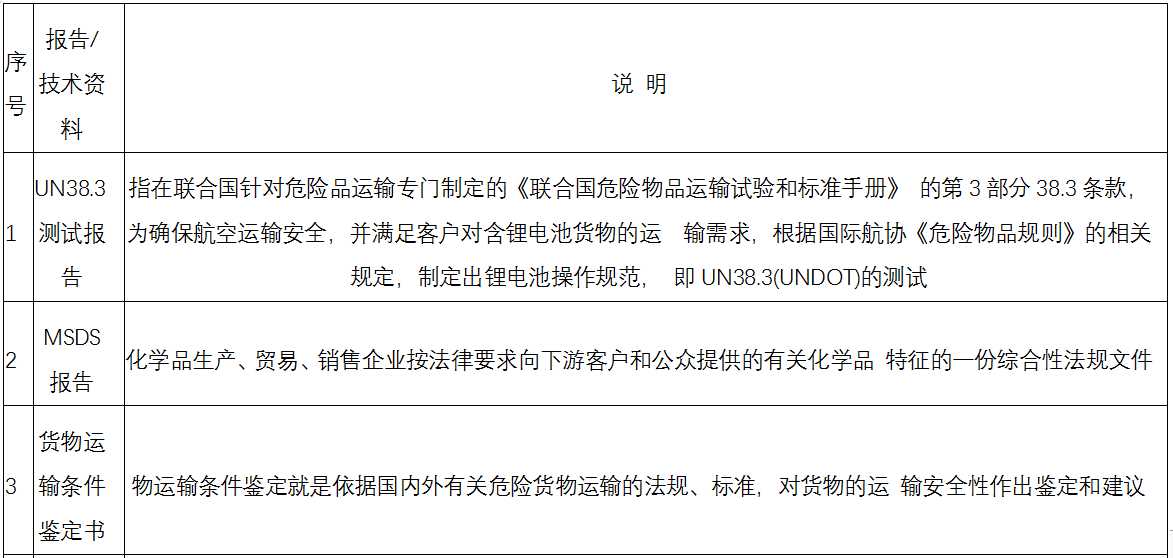

Lithium batteries belong to Class 9 hazardous materials, UN3480, and Class II hazardous materials. The main export by sea is to provide the following five types of documents.

2.4 Packaging labels

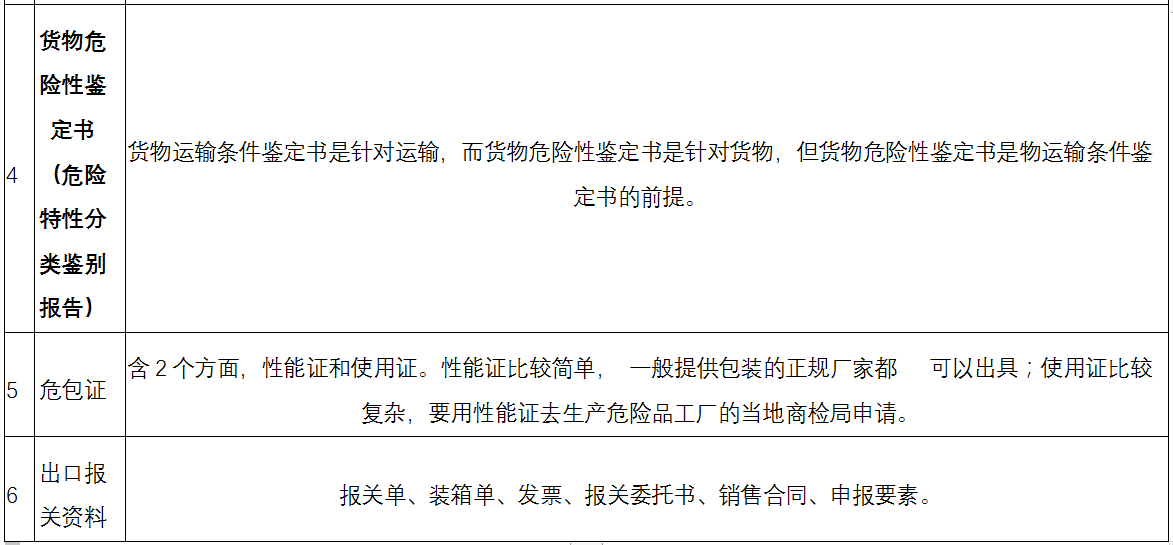

According to the requirements of the latest version of IMDG code (version 40-20) for lithium battery transportation labels, Table 6 is a unique transportation label for Class 9 dangerous goods in lithium battery packs

3、 Packaging requirements for lithium battery transportation

Battery products are getting bigger and bigger. In recent years, energy storage products (mobile energy storage, household energy storage, and grid connected energy storage) have become very popular. The core of energy storage products is lithium batteries, which are characterized by high density (small size, large weight). The packaging of these products is more prone to problems during transportation, such as crushed packaging, packaging damage, and cargo damage.

3.1. Why do we need to conduct transportation packaging testing when UN38.3 and dangerous packaging boxes are used for packaging?

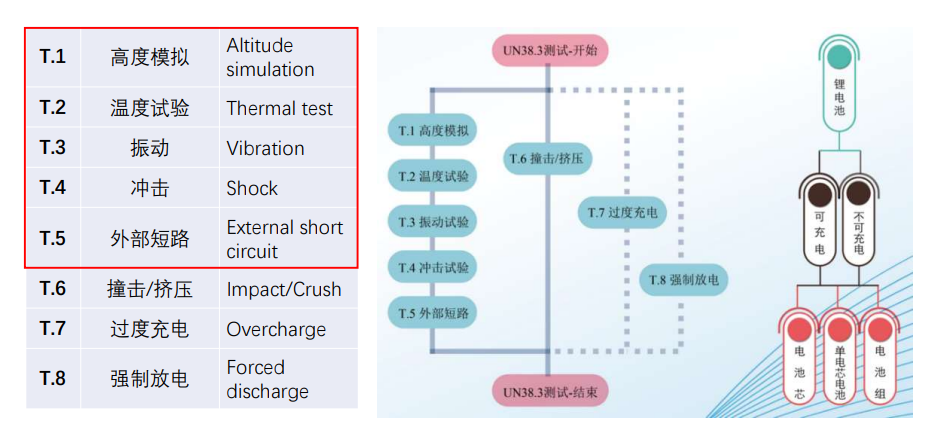

UN38.3 Test object: Battery, the test items are as follows:

The hazardous packaging certificate is a solution to the problem of hazardous packaging boxes. On November 22, 2021, the General Administration of Customs officially released the SN/T0370-2021 'Export Dangerous Goods Packaging Inspection Regulations' series of standards in Announcement No. 97 of 2021. It will be officially implemented on June 1, 2022.

The SN/T 0370 'Regulations for the Inspection of Packaging of Dangerous Goods for Export' series of standards are divided into three parts:

Part 1: General Provisions

Part 2: Performance Inspection

Part 3: Use Identification

SN/T 0370 'Regulations for the Inspection of Packaging of Dangerous Goods for Export - Part 2: Performance Inspection' mainly evaluates dangerous packaging boxes, with Chapter 5: Inspection Content

5.1 Drop test

5.2 Air tightness (sealing) test

5.3 Hydraulic test

5.4 Stacking test

5.5 Permeability test

5.6 Liquid sealing test

All the above tests do not pay much attention to the stress in the transportation environment of the packaging, which is why the transportation packaging that has undergone the above tests still has problems.

3.2. What is transportation packaging

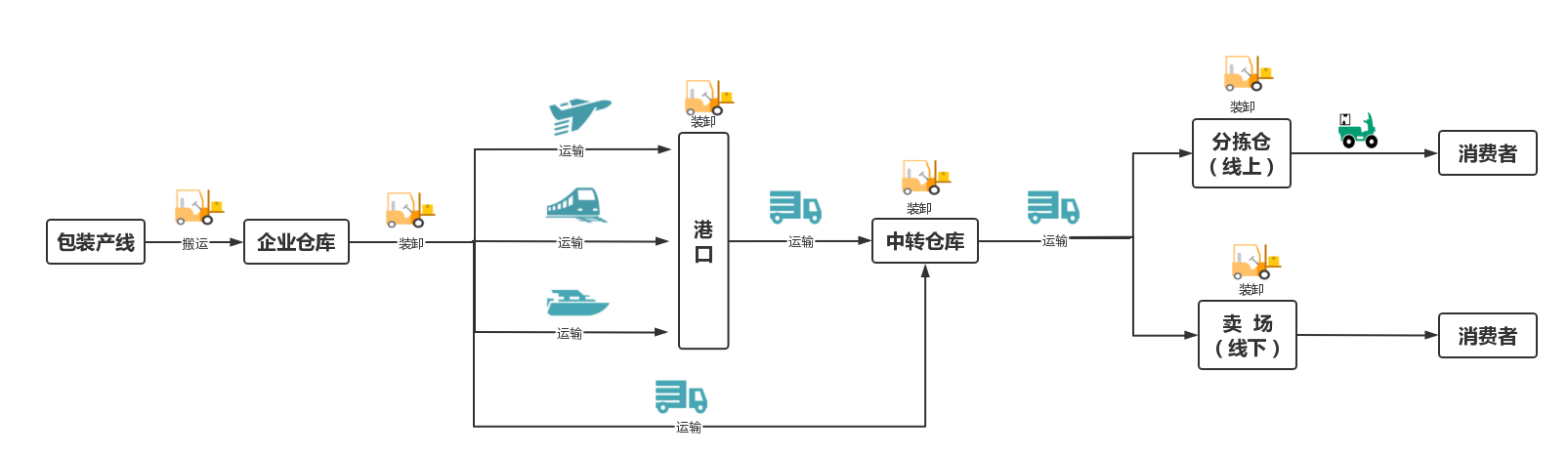

In the process of product circulation, packaging with the main purpose of storage, loading and unloading, and transportation is called transportation packaging. It has the function of protecting the safety of the production port, facilitating storage, loading and unloading, transportation, handover, and inspection.

3.3. What standards are used for transportation packaging testing? What tests are you going to do?

Main testing standards: ISTA, ASTM D4169, GB/T 4857, etc.

Test items:

1. Environmental testing (temperature, humidity, salt spray, spray, immersion)

2. Stacking compression test

3. Packaging clamping force test

4. Self drop test

5. Rotating drop

6. Horizontal/inclined impact test

7. Vibration testing (sine constant frequency, sine variable frequency, random)

8. Overturning test

9. Rolling test

10. Stability testing

11. Hazardous Material Impact Test

12. Collision/Impact Testing

13. Low pressure test

14. Forklift Handling Test

15. Field road test

3.4 How to design transportation packaging?

The transportation packaging design follows a 6-step or 5-step approach.

1. Determine the circulation environment conditions

2. Determine product brittleness value

3. Improve or redesign the product to increase its brittleness value

4. Select cushioning materials for cushioning packaging design and optimization

5. Design and produce prototype packaging

6. Prototype packaging testing and evaluation

epilogue

UN38.3 test reports, transportation appraisal reports, classification appraisal reports, MSDS, hazardous package certificates, etc. are all compliant materials for lithium battery transportation and are mandatory. It is to solve the problem of smooth shipment.

Transportation packaging testing is a solution to the problem of obtaining a sense of quality.