1、 Basic information of the standard:

Standard Name: Overview and Guidelines for Environmental Testing

Standard number: GB/T 2421-2020/IEC60068-1: 2013

This standard replaces GB/T 2421.1-2008 'Overview and Guidelines for Environmental Testing'

This standard was issued on June 2, 2020 and implemented on December 1, 2020.

This standard is under the jurisdiction of TC8 (National Technical Committee for Standardization of Environmental Conditions and Environmental Testing of Electrical and Electronic Products) and is implemented by TC8/SC2 (Climate and Environmental Testing Branch of National Technical Committee for Standardization of Environmental Conditions and Environmental Testing of Electrical and Electronic Products). The competent department is the National Standardization Management Committee.

Scope of this standard:

This standard includes a series of environmental testing methods and their severity levels, and specifies various atmospheric conditions for measurement and testing, used to evaluate the working ability of test samples in the expected transportation, storage, and various usage environments.

This standard is mainly applicable to electrical and electronic products, but is not limited to this. It can also be used in other fields when needed.

Other environmental testing methods specific to individual types of test samples can be specified in relevant specifications.

This standard provides a framework for the tailoring process of environmental testing to assist in the development of test specifications through appropriate testing methods and severity levels.

This standard provides a series of unified and repeatable environmental, climatic, mechanical, and combination tests for product specification developers and product testers, and includes standard atmospheric conditions for measurement and testing.

These test methods are based on existing international engineering experience and appraisal opinions, and are mainly used to provide the following performance information of test samples:

A) Capable of operating under specific temperature, pressure, humidity, mechanical stress, or other environmental conditions, or a combination of these conditions;

B) Capable of withstanding the conditions of transportation, storage, and installation.

Note 1: The IEC60721 series of standards provide a classification system for environmental conditions and provide relevant definitions.

The test methods in this standard can be used to compare the performance of sampled products. In order to evaluate the quality or service life of a given production batch of products, these methods are used according to the corresponding sampling plan and supplemented by appropriate auxiliary tests if necessary.

Note 2: ISO defines' quality 'as the degree to which a set of inherent characteristics meet the requirements.

Note 3: Service life: Under given conditions, the time interval starts from a given moment and ends when the strength of the fault becomes unacceptable or when the failure causes the item to be deemed irreparable.

In order to provide tests suitable for different environmental conditions and intensities, some test procedures have multiple severity levels. By individually or comprehensively

Change time, temperature, air pressure, or other determining factors to obtain these different levels of severity.

Environmental testing and its severity level should be determined based on the actual severity level that a specific test sample may encounter. This standard provides environmental protection

The framework and necessary stages of the environmental experiment tailoring process. Environmental test tailoring can be used to develop relevant test specifications for specific samples.

Reference standard atmospheric conditions:

——- Temperature: 20 ℃;

——- Air pressure: 101.3 kPa (1013mbar).

Note: Due to the fact that relative humidity cannot be corrected through calculation, it is not specified.

If the parameters to be measured vary with temperature or pressure, and their variation pattern is known, the parameter values should be measured according to the conditions specified in 4.3. If necessary, the reference standard atmospheric parameter values mentioned above can be corrected by calculation.

Standard atmospheres for arbitration measurement and testing:

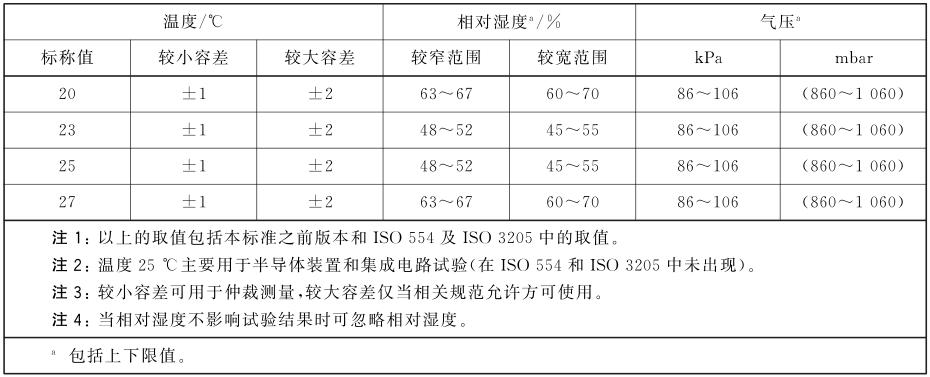

If the measured parameters depend on temperature, pressure, and humidity, and the variation pattern is unknown, the atmospheric conditions should be selected from Table 1.

Table 1 Standard atmospheric conditions for arbitration measurement and testing

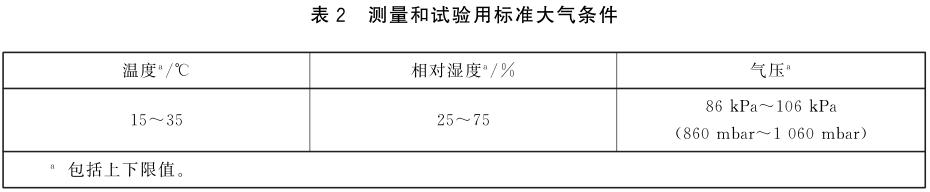

Standard atmospheric conditions for measurement and testing:

The range of standard atmospheric conditions used for measurement and testing is shown in Table 2.

As part of the test sample experiment, it is necessary to keep the changes in temperature and relative humidity to a minimum during the series of measurements.

Note 1: Within the above specified range, for larger test samples or those that are difficult to maintain temperature in the test chamber, when allowed by relevant regulations, the range can be appropriately relaxed, with the lower limit extended to 10 ℃ and the upper limit extended to 40 ℃. The absolute humidity should not exceed 22 g/m3.

If the relevant regulations deem it impractical to measure under these standard atmospheric conditions, the actual measurement conditions shall be recorded in the test report.

Note 2: If it does not affect the test results, the relative humidity can be ignored.

Recovery conditions:

After the condition test and before the final measurement, the test sample should be stable at ambient temperature. The measurement is carried out after stabilization.

When the electrical parameters of the test sample change rapidly due to the influence of moisture absorption or surface condition, the 'controlled recovery conditions' specified in this standard are used. If the test sample is taken out of the wet box for about 2 hours, the insulation resistance significantly increases.

When the electrical parameters of the test sample are not rapidly affected by moisture absorption or surface conditions, recovery can be carried out under the specified test standard atmospheric conditions.

When recovery and measurement are not carried out in the same test chamber, there should be no condensation on the surface of the test sample when it is transferred into the measurement chamber.

Most of the test methods in IEC60068-2 provide suitable recovery conditions and duration, unless otherwise specified in relevant specifications, these specified conditions should be used.

Controlled recovery conditions:

Note 1: Controlled recovery conditions are also known as 'standard recovery conditions'.

The controlled recovery conditions are as follows:

——- Temperature: The actual laboratory temperature is ± 1 ℃, within the range specified in 4.3, which is between+15 ℃ and+35 ℃;

——- Relative humidity: 73%~77%;

——- Air pressure: 86 kPa~106 kPa (860 mbar~1060 mbar);

——- Recovery time: If it is different from the test method specified in IEC60068-2, it should be specified in the relevant specifications.

If different recovery conditions are required in specific circumstances, relevant regulations should be specified.

Note 2: Controlled recovery conditions can also be used for preprocessing.

Recovery program:

Within 10 minutes after the conditional test, place the test sample in a recovery box (if a separate test box is required). If relevant regulations require recovery

If the measurement is carried out immediately, it should be completed within 30 minutes after the test sample is removed from the recovery box, and the parameters that change the fastest should be measured first.

The difference between the temperature in the recovery box and the laboratory temperature should not exceed 1 ℃ to avoid moisture absorption or drying of the test sample when taken out of the recovery box. The recovery box should have good thermal conductivity and be able to strictly control the humidity inside the box.

Standard drying conditions:

If it is required to dry the test sample before measurement, unless otherwise specified in relevant specifications, it should be dried for 6 hours under the conditions specified in Table 3.

2、 Standard drafting unit:

3、ORT participated in drafting and published standards:

1. GB/T 35774-2017 'Specification for Performance Testing of Transport Packaging Components'

2. GB/T 4857.1-2019 'Basic Testing of Packaging, Transportation, and Packaging Components - Part 1: Marking Methods for Various Parts during Testing'

3. GB/T 4798.1-2019 'Classification of Environmental Conditions - Classification of Environmental Parameter Groups and Classification of Their Severity - Part 1: Storage'

4. GB/T 2421-2020 'Overview and Guidelines for Environmental Testing'

5. GB/T 2423.27-2020 'Environmental Testing - Part 2: Test Methods, Test Methods and Guidelines: Temperature/Low Pressure or Temperature/Humidity/Low Pressure Combined Tests'

6. GB/T 2423.51-2020 'Environmental Testing - Part 2: Test Methods - Test Ke: Flow Mixed Gas Corrosion Test'

7. GB/T 32065.8-2020 Marine Instruments - Environmental Testing Methods - Part 8: Temperature Change Test

8. GB/T 32065.10-2020 Marine Instruments - Environmental Testing Methods - Part 10: Salt Spray Test

9. GB/T 4797.9-2021 Classification of Environmental Conditions - Natural Environmental Conditions - Shock and Vibration Data Measured during Storage, Transportation, and Use

10. GB/T 2423.33-2021 Environmental Testing Part 2: Test Methods Test Kca: High Concentration Sulfur Dioxide Test

11. GB/T 2423.18-2021 Environmental Testing Part 2: Test Methods Test Kb: Salt Spray, Alternating (Sodium Chloride Solution)

12. NB/T 10279-2019 'Wet and Hot Environmental Conditions for Transmission and Transformation Equipment'

13. NB/T 10280-2019 'Wet and Hot Environmental Conditions and Technical Requirements for State Monitoring Devices Used in Power Grids'

14. YZ/T 0174-2020 Technical Requirements for Cold Chain Delivery Insulation Box

15. T/CPF 0012-2020 Guidelines for Testing Small Transport Packages for Express Delivery

16. T/CPF 0011-2020 Guidelines for Testing Electrical Transportation Packaging in E-commerce Logistics