1、 Basic information of the standard:

Standard name: Environmental testing Part 2: Test methods Test methods and guidelines: Temperature/low air pressure or temperature/humidity/low air pressure comprehensive test

Standard number: GB/T 2423.27-2020/IEC 60068-2-39: 2015

This section replaces GB/T2423.25-2008 'Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods - Test Z/AM: Low Temperature/Low Air Pressure Comprehensive Test' GB/T2423.26-2008 'Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods - Test Z/BM: High Temperature/Low Air Pressure Comprehensive Test' and GB/T2423.27-2005 'Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods - Test Z/AMD: Low Temperature/Low Air Pressure/Humidity Heat Continuous Comprehensive Test'.

This section was released on June 2, 2020 and implemented on December 1, 2020.

This part is under the jurisdiction of TC8 (National Technical Committee for Standardization of Environmental Conditions and Environmental Testing of Electrical and Electronic Products) and is executed by TC8/SC2 (Climate and Environmental Testing Branch of National Technical Committee for Standardization of Environmental Conditions and Environmental Testing of Electrical and Electronic Products). The competent department is the National Standardization Management Committee.

Scope of this standard:

This part of GB/T2423 provides testing methods for temperature/low air pressure or temperature/humidity/low air pressure comprehensive tests of equipment or components

Law and its guidelines.

The purpose of comprehensive testing is to study the degree of impact of temperature/low air pressure or temperature/humidity/low air pressure comprehensive testing on equipment or components.

Comprehensive testing methods are used to evaluate electrical, mechanical, or other physical properties.

Test method:

All values of test parameters such as low temperature, high temperature, low air pressure, humidity, test time, and operating status of test samples should be

Selected from IEC60068-2 and related specifications.

The test time should be calculated from the time when the test sample reaches temperature stability under low air pressure conditions. Temperature stability according to IEC60068-1

Regulations.

The test should preferably be conducted under low wind speed conditions.

1. Recommended comprehensive test:

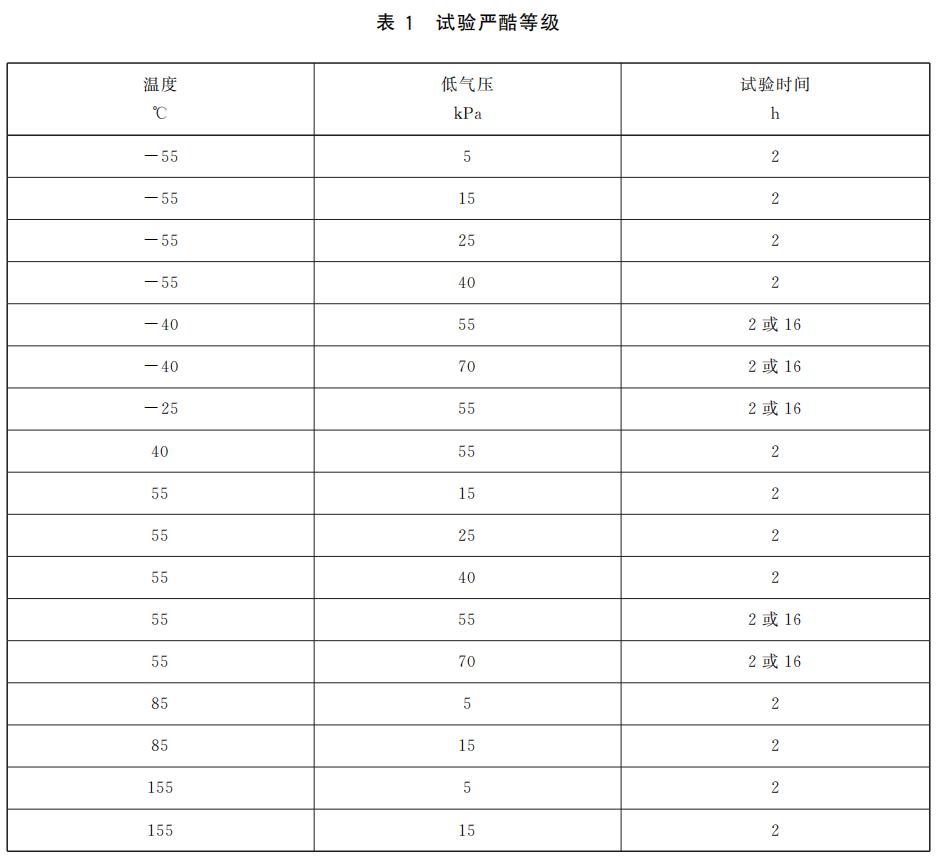

Temperature, low air pressure, and test time can be selected from Table 1.

2. Temperature/low air pressure test:

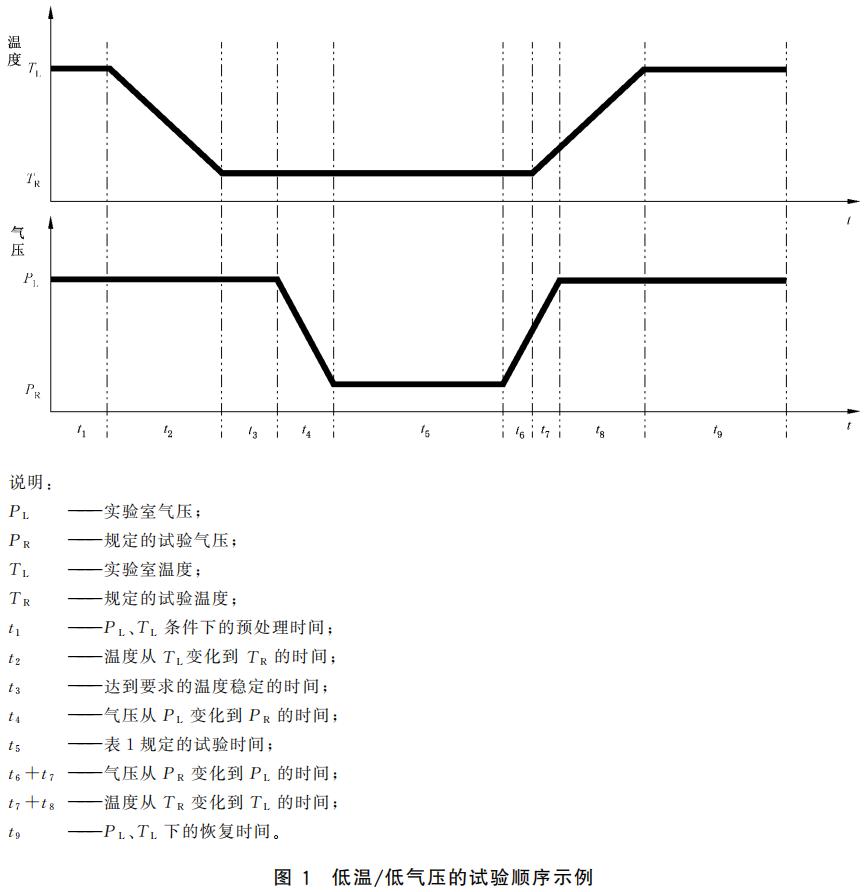

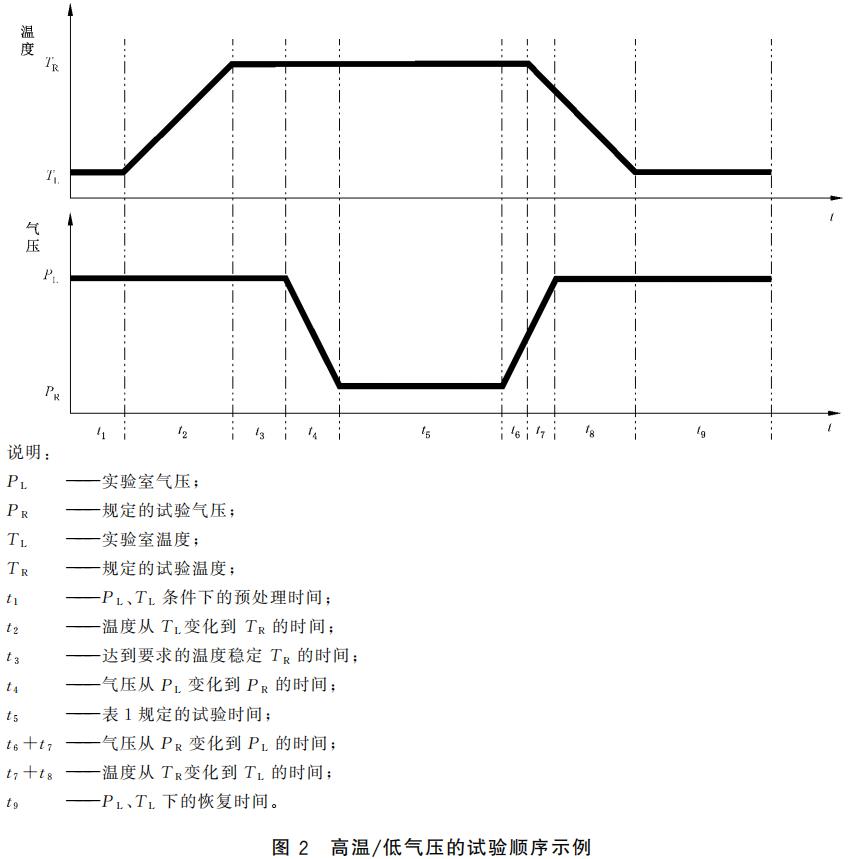

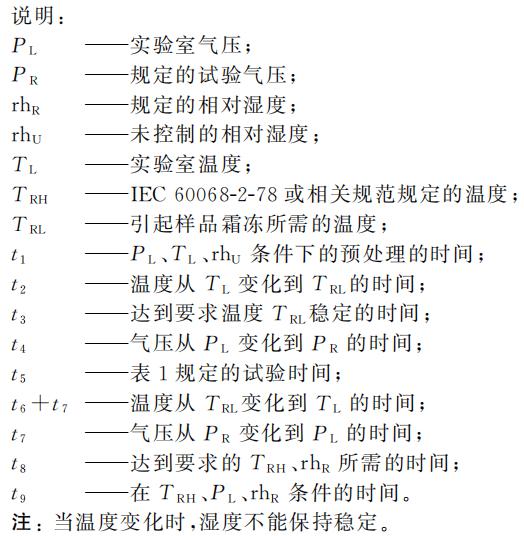

Figures 1 and 2 provide examples of temperature/low pressure tests.

3. Temperature/humidity/low air pressure test:

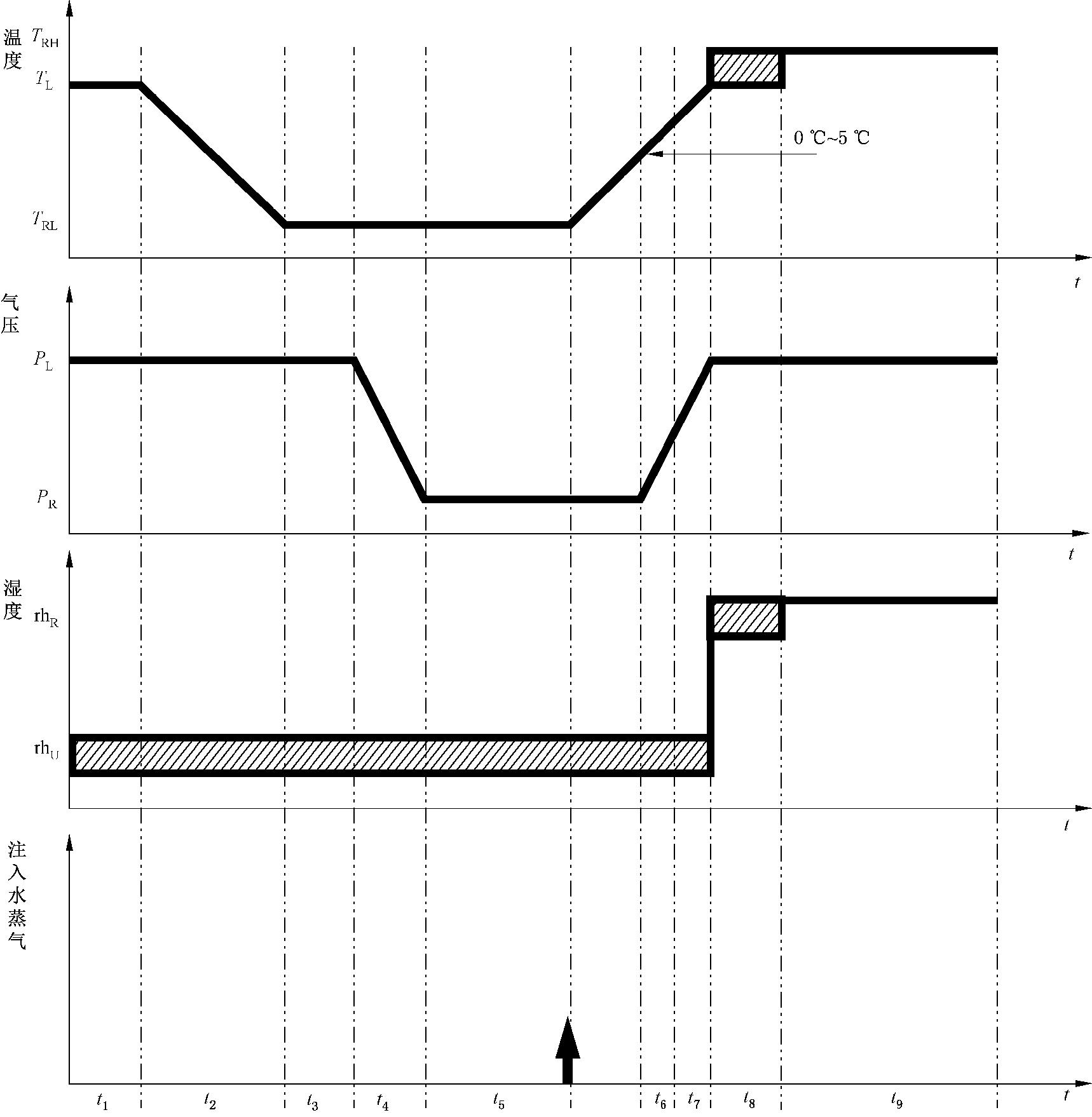

Figure 3 provides an example of temperature/humidity/low air pressure testing.

Figure 3 Example of Temperature/Humidity/Low Air Pressure Test Sequence

2、 Environmental effects:

1. The temperature/low-pressure comprehensive test generally has the following effects on the test sample:

a) Compared to the specified values, the changes in surface temperature and temperature gradient of the heat dissipation sample are caused by the decrease in convective coefficient under low air pressure. Although using a higher test temperature under normal air pressure can achieve an increase in surface temperature, this test temperature value cannot be determined and the correct temperature gradient cannot be achieved without combining low air pressure.

b) The changes in low pressure gas and air dielectric properties result in changes in the functionality and safety performance of the test sample. Under low air pressure, especially when combined with high temperature, the dielectric strength of the air significantly decreases, resulting in an increased risk of arc, surface or corona discharge.

c) Changes in material properties caused by low or high temperatures increase the risk of deformation or rupture of sealing equipment or components under low air pressure.

2. Mainly caused by temperature, the impact of significant acceleration due to low air pressure is:

a) As the mechanical and electrical properties of various parts of the test sample change, plasticizers and plastic degradation products evaporate. These volatile products can condense on nearby surfaces and/or undergo characteristic changes, corrosion, and/or degradation.

b) Lubricant evaporation may block moving parts.

c) Dissolved gas escapes from the liquid, and the reduced low pressure may cause brief boiling and may leak the liquid.

3、 Expansion: Factors affecting low atmospheric pressure

-Below standard atmospheric pressure:

Above sea level, low air pressure has the following effects on products:

——Gas or liquid may leak from sealed containers;

——Pressure vessel rupture;

——Changes in the physical and chemical properties of low-density materials;

——As the air pressure decreases, the discharge voltage, corona voltage, and breakdown voltage between the electrodes of the product decrease, and the product may fail or malfunction due to arc or corona (Bashen's law states that in a uniform electric field, for a given electrode shape and material, the breakdown voltage of air depends on the product of air pressure and electrode air gap);

——Reduce the efficiency of air convection and conduction heat dissipation;

——Expected acceleration of physical effects, such as volatile plasticizers, lubricant evaporation, etc.

-Above standard atmospheric pressure:

The high pressure that exists in natural basins and mines can generate significant mechanical pressure on sealed containers.

4、 Standard drafting unit:

5、ORT participated in drafting and published standards:

1. GB/T 35774-2017 'Specification for Performance Testing of Transport Packaging Components'

2. GB/T 4857.1-2019 'Basic Testing of Packaging, Transportation, and Packaging Components - Part 1: Marking Methods for Various Parts during Testing'

3. GB/T 4798.1-2019 'Classification of Environmental Conditions - Classification of Environmental Parameter Groups and Classification of Their Severity - Part 1: Storage'

4. GB/T 2421-2020 'Overview and Guidelines for Environmental Testing'

5. GB/T 2423.27-2020 'Environmental Testing - Part 2: Test Methods, Test Methods and Guidelines: Temperature/Low Pressure or Temperature/Humidity/Low Pressure Combined Tests'

6. GB/T 2423.51-2020 'Environmental Testing - Part 2: Test Methods - Test Ke: Flow Mixed Gas Corrosion Test'

7. GB/T 32065.8-2020 Marine Instruments - Environmental Testing Methods - Part 8: Temperature Change Test

8. GB/T 32065.10-2020 Marine Instruments - Environmental Testing Methods - Part 10: Salt Spray Test

9. GB/T 4797.9-2021 Classification of Environmental Conditions - Natural Environmental Conditions - Shock and Vibration Data Measured during Storage, Transportation, and Use

10. GB/T 2423.33-2021 Environmental Testing Part 2: Test Methods Test Kca: High Concentration Sulfur Dioxide Test

11. GB/T 2423.18-2021 Environmental Testing Part 2: Test Methods Test Kb: Salt Spray, Alternating (Sodium Chloride Solution)

12. NB/T 10279-2019 'Wet and Hot Environmental Conditions for Transmission and Transformation Equipment'

13. NB/T 10280-2019 'Wet and Hot Environmental Conditions and Technical Requirements for State Monitoring Devices Used in Power Grids'

14. YZ/T 0174-2020 Technical Requirements for Cold Chain Delivery Insulation Box

15. T/CPF 0012-2020 Guidelines for Testing Small Transport Packages for Express Delivery

16. T/CPF 0011-2020 Guidelines for Testing Electrical Transportation Packaging in E-commerce Logistics